Orientation

Orient the part in relation to the printing bed. You can orient the part to a surface, or to achieve the maximum or minimun build height.

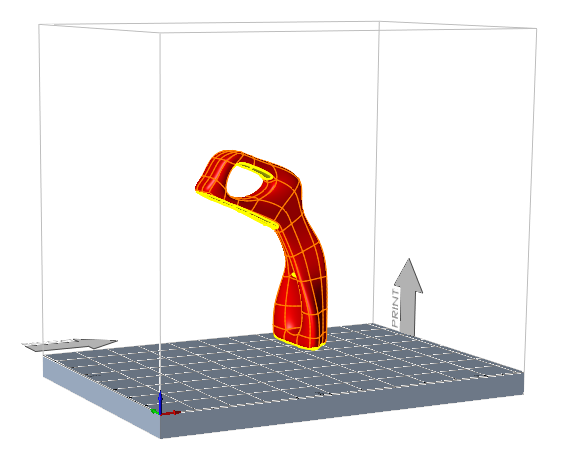

- For surfaces on the part with angles of less than 45 degrees, support is

required. These areas are shown in yellow and update automatically as the

part is rotated using the Move

tool.

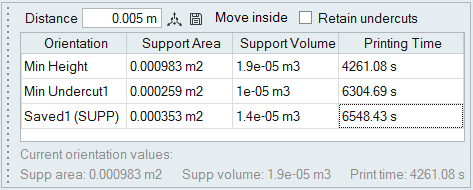

tool. - If you rotate the part or create new orientaitions, the Current orientation values update automatically. Select a row in the Orientation table to restore that orientation.

- If the part accidentally extends outside of the printing bed, select the Move Inside option on the Orientation table to place it inside of the printing bed.

- By default, undercuts are only shown in yellow when the Orientation tool is active. Enabling the Retain Undercuts option on the Orientation table makes the undercuts visible when using other tools. This is useful when you are modifying the geometry and want to see how the undercuts change as a result.