Tutorial: Grounded Fastener Optimization

Enable grounded fastener optimization to improve load distribution into the supports.

- Set up and run a baseline analysis of a hanger bracket to establish realistic design targets

- Create a defeatured model to set up and run a standard topology optimization

- Enable fastener optimization to improve load distribution into the supports

Overview: Fastener Load Optimization

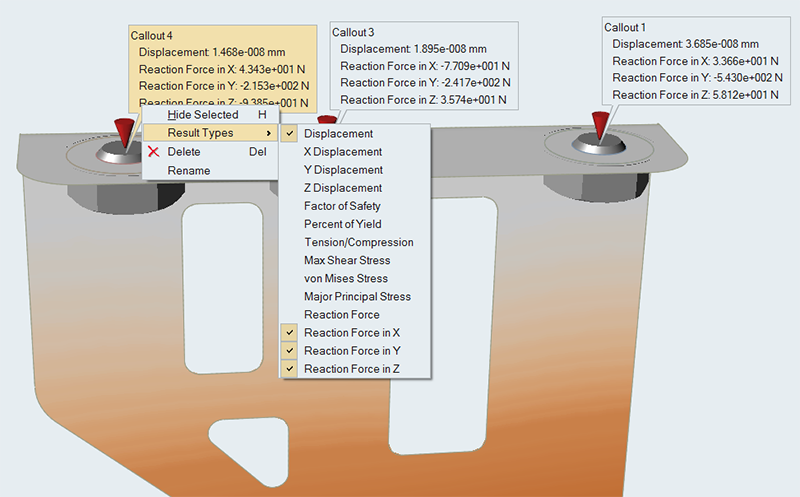

Evenly distributing or limiting the maximum force in all bolts, screws, and other connections in a structure is a common aim of good design practice. When structures become complex in shape or loading, it can be difficult to achieve this objective. One approach is to use topology optimization to redistribute material away from direct load paths so that underutilized fasteners carry more of the applied load. Inspire provides the ability to constrain the load in a grounded screw or grounded bolt to achieve improved load distribution in a structure.

- In many structures, loads are not uniformly applied and geometry is often non-symmetric. This can lead to large variations in the forces that the fasteners and connection points carry.

- Changing the topology of the structure will change the amount of load in each fastener.

- By limiting the maximum load in a fastener or set of fasteners, the topology generated by Inspire can more evenly distribute the resultant forces, reducing the maximum stresses and helping torque retention.

Set up the Hanger Model

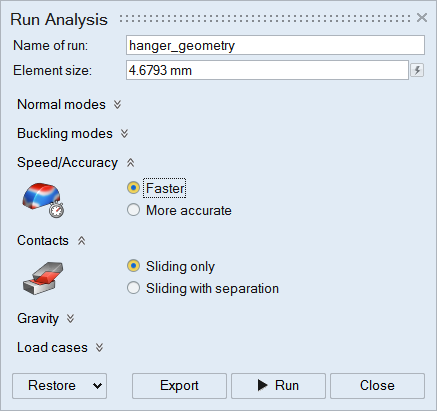

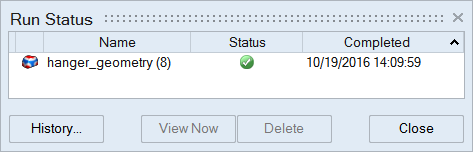

Run a Baseline Analysis

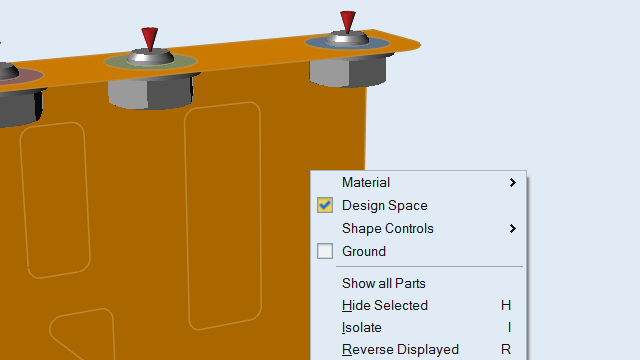

Prepare the Model for Topology Optimization

The best starting point for topology optimization is a design region without any predefined cutouts. In many cases, the patch tool can be used to fill holes in surface models.

icon on the

icon on the