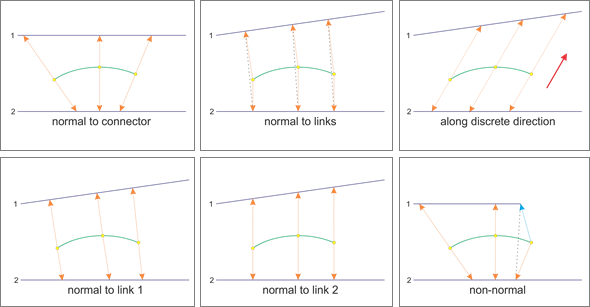

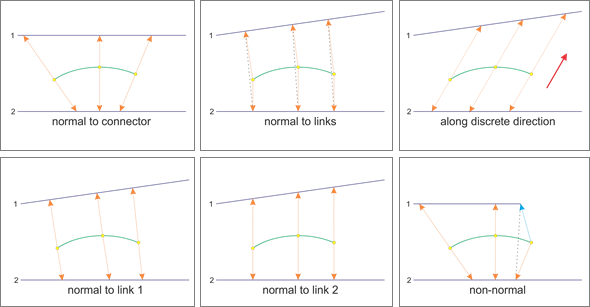

Projection Control Methods for Area Connectors

Use the projection control methods to control how projection should be performed for area connectors.

View new features for Engineering Solutions 2020.1.

HyperWorks Engineering Solutions is a modeling and visualization environment for NVH, Crash, CFD, Drop Test and Aerospace using best-in-class solver technology.

Discover Engineering Solutions functionality with interactive tutorials.

Noise, Vibration and Harshness (NVH) is an important vehicle attribute that directly affects the customer experience.

The Crash application offers a tailored environment in HyperWorks that efficiently steers the Crash CAE specialist in CAE model building, starting from CAD geometry and finishing with a runnable solver deck in Radioss, LS-DYNA and PAM-CRASH 2G.

HyperWorks offers high quality tools for CFD applications enabling the engineer to perform modeling, optimization and post-processing tasks efficiently.

The Drop Test Manager is an automated solution that allows you to either simulate a single drop test or a choice of multiple iterations with the aim of finding the sensitivity of process variables like initial orientation and drop height in a typical drop test by controlling the run parameters and conditions with ease.

Many essential utility tools using HyperWorks-Tcl have been developed over the years to support Aerospace customers. A few tools have been collected and upgraded to be compatible with this release.

Currently supported solver interface versions.

Load a different solver interface in Engineering Solutions.

Engineering Solutions uses three types of external interfacing.

Overview of the Abaqus Interface.

Overview of the ANSYS interface.

Overview of the LS-DYNA interface.

Overview of the Nastran interface.

Overview of the PAM-CRASH 2G interface.

Overview of the OptiStruct interface.

Overview of the Radioss interface.

A solver interface is made up of a template and a FE-input reader.

Support provided by the CAD readers and writers.

Browsers supply a great deal of view-related functionality in Engineering Solutions by listing the parts of a model in a tabular and/or tree-based format, and providing controls inside the table that allow you to alter the display of model parts.

Panels contains pre-processing and post-processing tools.

Create, edit, and cleanup geometry.

Learn about the different types of mesh you can create in HyperWorks.

Create connections between parts of your model.

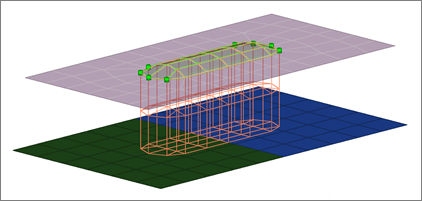

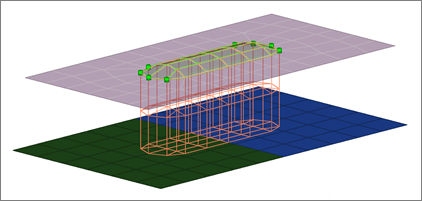

Connectors are geometric entities (not FE) used to create connections between components. Connectors are used to realize FE idealizations of the physical connection. Just as you create an FE mesh on a surface, you create FE connections by realizing a connector.

A connector definition describes the connection between multiple entities at a specific location.

Overview of connector terminology.

Overview of the process used to select the best routine for realization.

Learn about special connector realization types.

Use the projection control methods to control how projection should be performed for area connectors.

There are many advantages to the way connectors store information. Not only does this local storage allow you to edit the connector definition, it also allows you to review connector details and the quality of the realization.

Each individual connector can be placed in a user control mode using either the *CE_SetSpecificDetailById or *CE_SetSpecificDetail commands.

Most of the information stored in the connector entity can be exported to a master connectors file, which contains connector entity information such as location, link entity, link entity state, link entity rules. The exported file may also contain metadata information stored in the connector.

In addition to the master connectors file, the connectors reader also supports master weld file formats previously supported by the spotweld reader.

The spotweld feinput translator reads weld information from an ASCII file, such as a Master Weld File.

The FE configuration file (feconfig.cfg) is used to define custom welds such as ACM (Area Contact Method) and other special types.

Create weld points at a predefined pitch distance so that the model build process can continue without the need to wait for the published weld data from CAD. Autopitch is useful when working with elements, not geometry.

Create specialized connector realization types which can be used in fatigue calculations with the third party FEMSITE tool.

Attachments are an entity to facilitate the ease of joining subsystems.

Create, organize, and manage the CAE parts.

Perform automatic checks on CAD models, and identify potential issues with geometry that may slow down the meshing process using the Verification and Comparison tools.

Overview of how to build a finite element model.

Morph the shape of your finite element model.

Setup an Optimization in Engineering Solutions.

Convert finite element models to another solver format.

Study relationships between data vectors in results files.

Learn how to use post-processing functions.

Create connections between parts of your model.

Use the projection control methods to control how projection should be performed for area connectors.

ON THIS PAGE

Use the projection control methods to control how projection should be performed for area connectors.

ON THIS PAGE

(c) 2020. Altair Engineering Inc. All Rights Reserved.