Front Suspension Systems

Front suspension supports the wheels in the front with the help of a solid axle. The front suspension stabilizes the vehicle to the road and helps to absorb the bumps of the road. There are two types of front suspension used in the Truck Library.

Front Solid Axle Suspension

- Wheel

- Wheel is a circular disc joined to a hub that is mounted on a shaft about which it may revolve and bear a load.

- Wheel Hub

- The wheel hub assembly holds the wheel parts together. The assembly contains the wheel bearings, which allows the wheels to turn steadily.

- Axle

- An axle is a fixed bar on which a wheel or a pair of wheels revolve.

- Knuckle

- It is one of the suspension components which allows the tire to turn

with ease. It is type of ball joint located at the end of each

tierod.Figure 2.

- Leaf Springs

- Leaf springs are used in front solid axle suspension and are mounted to

the frame at two points. The ends of the leaf spring can either tie to

the top of the rods, or to the top of the solid axle. The axle receives

its vertical support from a leaf spring (leaf springs were often used

for support in more than one direction). Figure 3.

- Front Solid Axle Suspension with Trailing Arm

- Front solid axle suspension with trailing arm has a suspension system

for a vehicle frame having an elongated, supported body (trailing arms),

and a steering axle positioned below the supported body to support a

portion of vehicle weight. The front solid axle suspension with trailing

arm built through the Assembly Wizard is displayed

in the MotionView window.Figure 4.

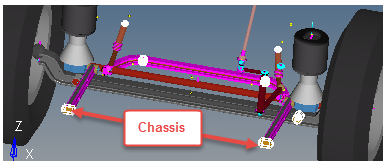

- Chassis

- Chassis is a steel frame which is rectangular in shape is supported on

springs and is eventually attached to an axle, which holds the body of

an automotive vehicle. In the following image the highlighted parts in

the truck represents the chassis.Figure 5.

- Trailing Arm

- Trailing Arm is a suspension element consisting of a longitudinal member

with first, second and third arms, each rigidly connected and it pivots

from the body at its forward end and has a wheel hub attached to its

trailing end. Figure 6.

- Lateral Arm

- Trailing arms designs are poor at maintaining axle position laterally,

which makes the use of a lateral link to hold axle position

necessary.Figure 7.

- Air Springs

- Air spring used in the front solid axle suspension has the following

benefits:

- It helps to maintain a constant vehicle height by adjusting the deflection rate automatically for changing vehicle loads.

- It has lower deflection rate when compared to traditional leaf springs exerting the same force giving the system greater capacity for absorbing shocks for a given displacement between the axle and the frame.