OS-T: 6080 Sine Sweep Fatigue Analysis (SN Damage)

This tutorial provides an overview of fatigue life of structures under Sinusoidal Loading,

The following file found in the optistruct.zip file is needed to perform this tutorial. Refer to Access the Model Files.

bracket-frf.fem

or

A copy of the model file used in this tutorial is available on <install_directory>/tutorials/hwsolvers/optistruct.

Launch HyperMesh and Set the OptiStruct User Profile

Import the Model

Set Up the Model

Create TABLED1 Load Collector

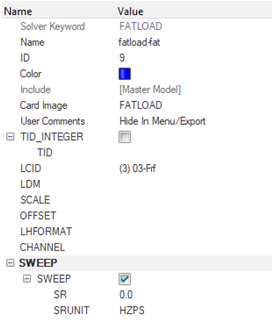

Define FATLOAD Load Collector

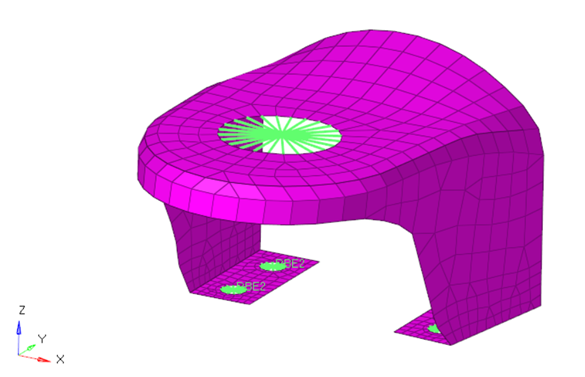

The model has a Frequency Response loadstep defined, which is used to define the FATLOAD.

Define FATEVNT Load Collector

Create a random response event for the FATLOAD_RAND created.

- In the Model Browser, right-click and select .

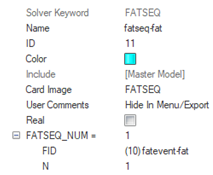

- For Name, enter fatevent-fat.

- For Card Image, select FATEVNT.

- For FATEVNT_NUM_FLOAD, enter 1.

- Select fatload-fat for FLOAD in the Loadcol field.

Define FATSEQ Load Collector

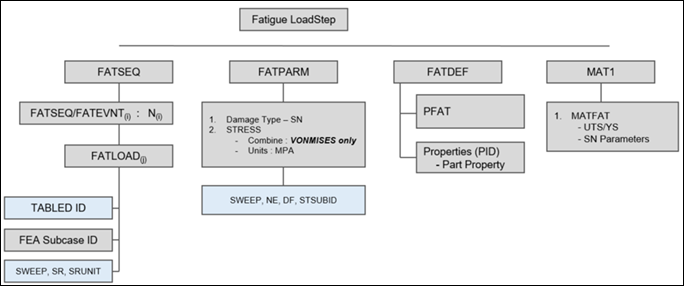

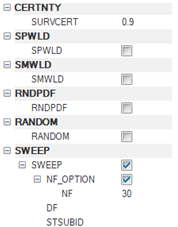

Define Fatigue Parameters

Define Fatigue Material Properties

The material curve for the fatigue analysis can be defined on the MAT1 card.

Define PFAT Load Collector

- In the Model Browser, right-click and select .

- For Name, enter pfat-fat.

- For Card Image, select PFAT.

- Set LAYER to WORST.

- Set FINISH to NONE.

- Set TRTMENT to NONE.

- Set Kf to 1.0.

Define FATDEF Load Collector

- In the Model Browser, right-click and select .

- For Name, enter fatdef-fat.

- Set the Card Image to FATDEF.

- Activate PTYPE and PSHELL in the Entity Editor.

- Edit FATDEF_PSOLID_NUMIDS to 1.

- Select new_bracket for PID and pfat-fat for PFATID.

Define the Fatigue Load Step

- In the Model Browser, right-click and select .

- For Name, enter 04-Fatigue.

- Set the Analysis type to fatigue.

- For FATDEF, select fatdef-fat.

- For FATPARM, select fatparm-fat.

- For FATSEQ, select fatseq-fat.

.

.

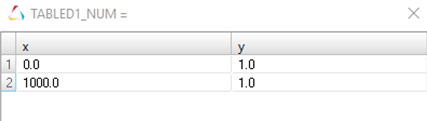

below TABLED1_NUM

and enter the values in the pop-out window, as shown below.

below TABLED1_NUM

and enter the values in the pop-out window, as shown below.

to open the

to open the