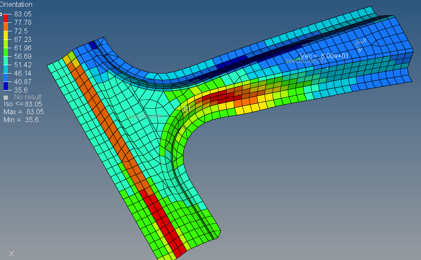

Use the Laminate tool to calculate fiber angles and thickness changes with respect to

an element material system.

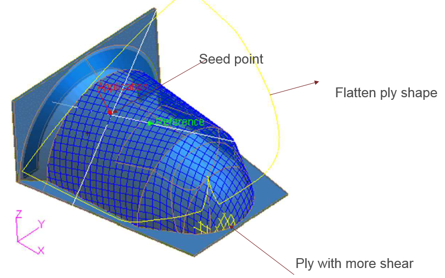

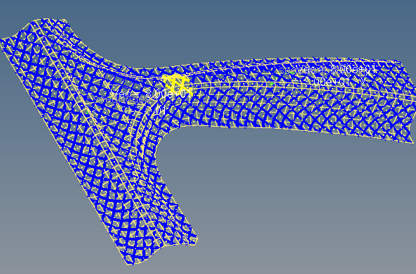

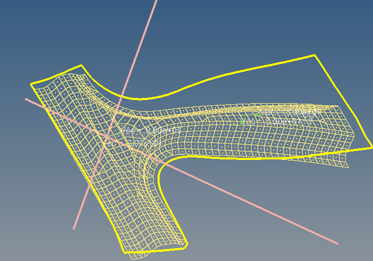

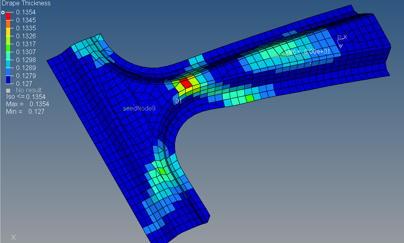

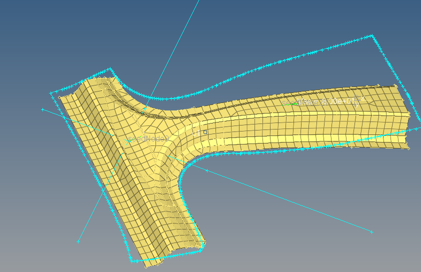

This tool creates a distribution table of drape angle changes, change the thickness

of each ply, and flatten the shape of a ply that needs to be fabricated before

laying on the mold.

Fiber angle changes with respect to a material system when a flat composite sheet is

laid on surfaces of a part which is highly curved in bi-directions. This also

changes the ply thickness. It is no longer the nominal ply angle ( 0,45,-45, 90). If

the change in angle or thickness is significant, it will lead to a change in the

stiffness of a part.

Note: The Laminate tool is available in the OptiStruct and Abaqus user

profiles.