ACU-T: 4000 Transient Dam Break Simulation

Prerequisites

This tutorial introduces you to the workflow for setting up an AcuSolve transient dam break simulation using HyperWorks CFD. Prior to starting this tutorial, you should have already run through the introductory HyperWorks tutorial, ACU-T: 1000 HyperWorks UI Introduction, and have a basic understanding of HyperWorks CFD and AcuSolve. To run this simulation, you will need access to a licensed version of HyperWorks CFD and AcuSolve.

Prior to running through this tutorial, copy HyperWorksCFD_tutorial_inputs.zip from <Altair_installation_directory>\hwcfdsolvers\acusolve\win64\model_files\tutorials\AcuSolve to a local directory. Extract ACU-T4000_dambreak2D.x_t from HyperWorksCFD_tutorial_inputs.zip.

Problem Description

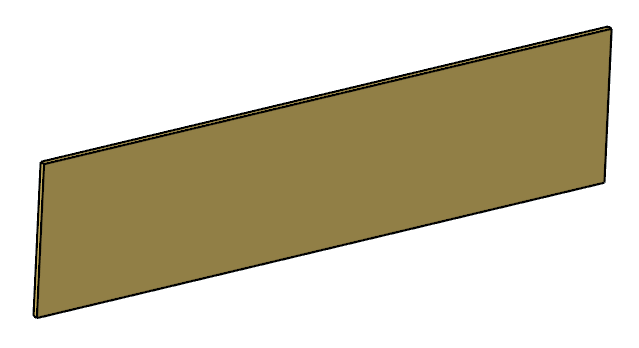

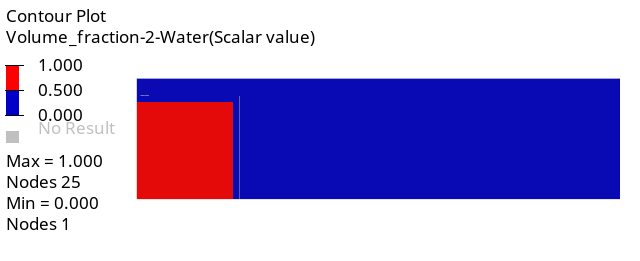

The problem to be addressed in this tutorial is shown schematically in the figure below. It consists of a square water column held in place by the reservoir walls. At time t=0, the walls are removed and the water column is now free to flow out. The simulation can be used to visualize and study the surge patterns as the column of water rushes out, as in a dam wall break.

Start HyperWorks CFD and Create the HyperMesh Model Database

Import and Validate the Geometry

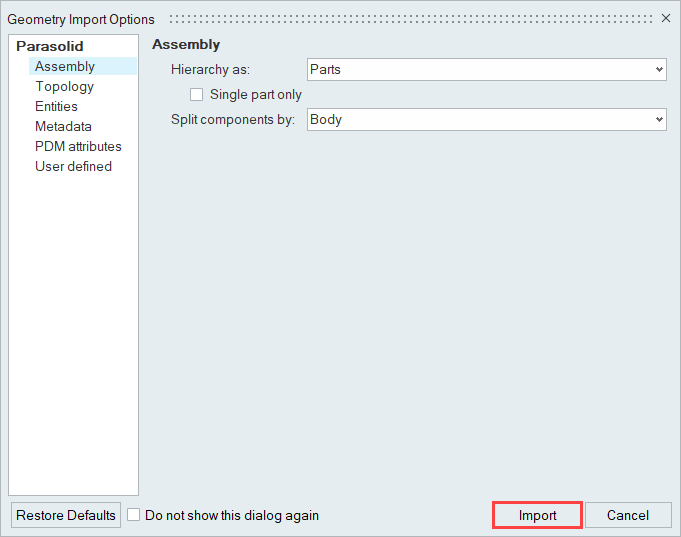

Import the Geometry

Validate the Geometry

Set Up the Problem

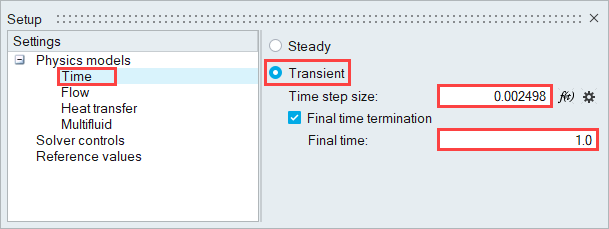

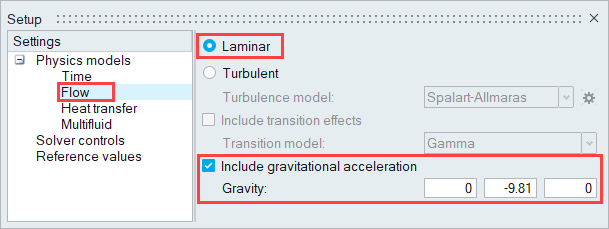

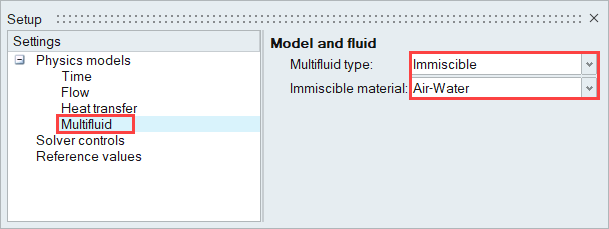

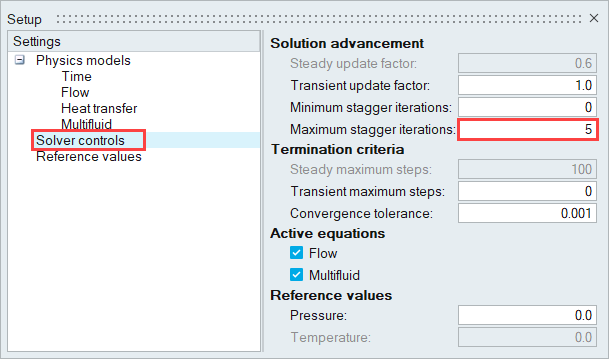

Set Up the Simulation Parameters and Solver Settings

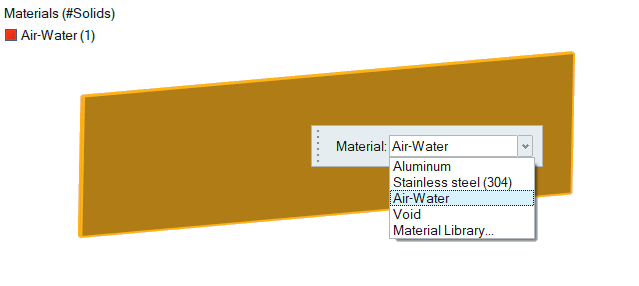

Assign Material Properties

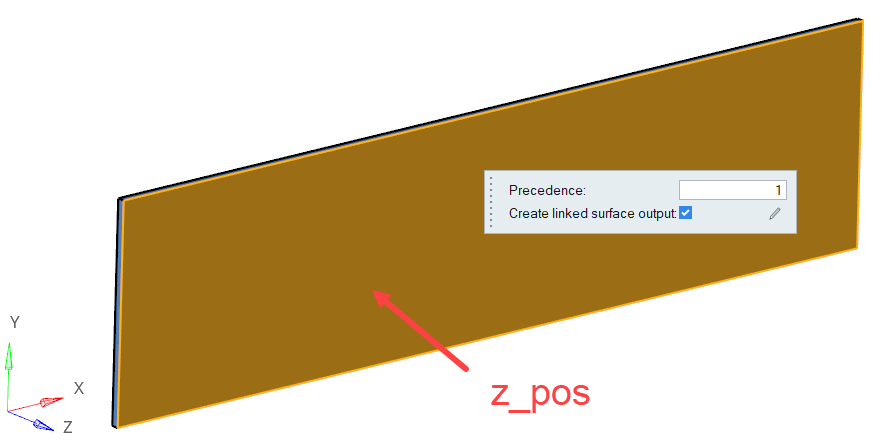

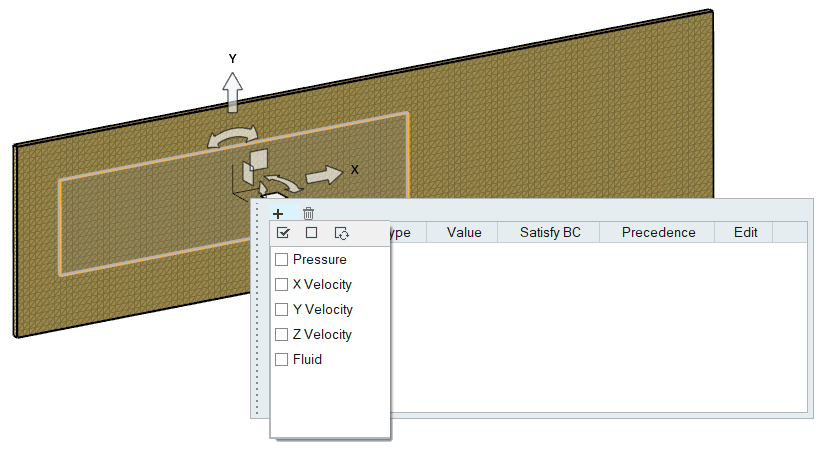

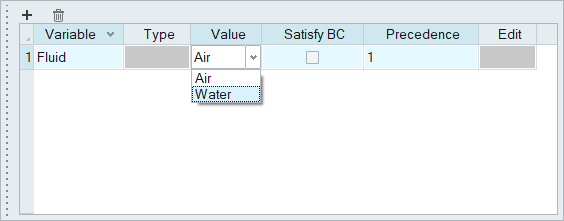

Define Flow Boundary Conditions

Generate the Mesh

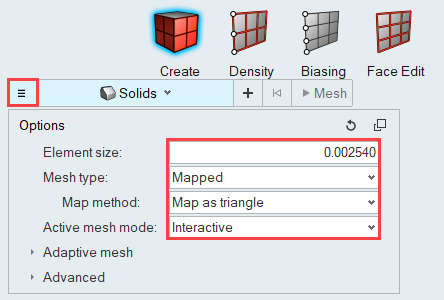

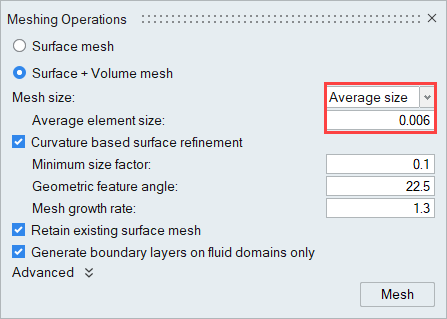

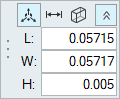

In this step, first you will create a surface mesh using the Interactive meshing tool; then, you will specify a global mesh size and growth rate for the model and generate the volume mesh using the Batch tool in the Mesh ribbon.

Create Surface Mesh

Generate Volume Mesh

Define Nodal Outputs and Nodal Initial Conditions

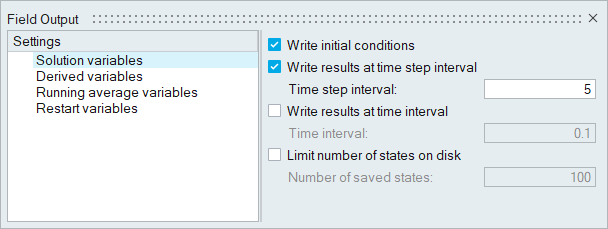

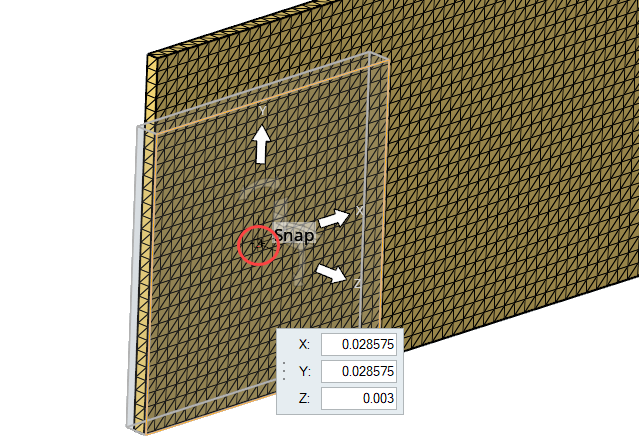

In this step, you will define the nodal output frequency and then specify the nodal initial conditions for the water column.

Define Nodal Output Frequency

Define the Nodal Initial Conditions

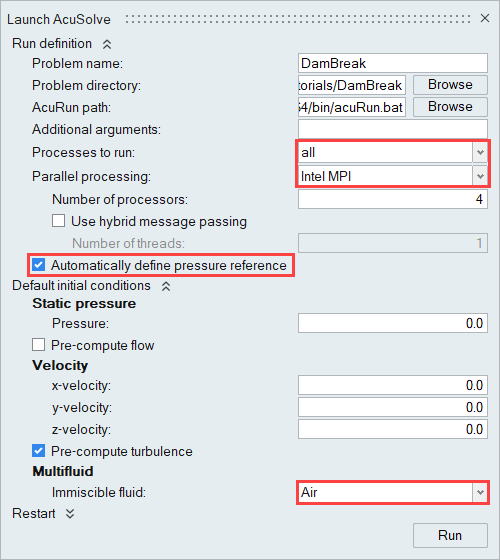

Run AcuSolve

Post-Process the Results with HyperView

In this step, you will create an animation of the water flow as it surges once the walls restricting the water column are removed.

Open HyperView and Load the Model and Results

Create the Water Flow Animation

Save the Animation

Summary

In this tutorial, you successfully learned how to set up and solve a multiphase flow problem using HyperWorks CFD and AcuSolve. You started by importing the geometry and then completed the flow set up. Once the volume meshing was done, you specified the field initial conditions for the water column using the zone initialization tool. Once the solution was computed, you post-processed the results in HyperView. Here, you generated an animation of the water flow as it surged once the dam walls were removed.

on the

on the

on the Standard Views toolbar.

on the Standard Views toolbar.

.

. to play the animation in the graphics area.

to play the animation in the graphics area.