HL-T: 1030 Multiaxial Strain-Life (E-N)

- Import a model to HyperLife

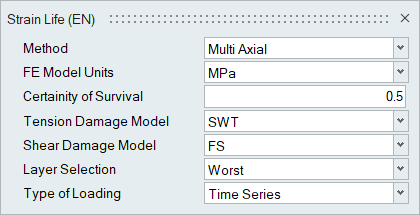

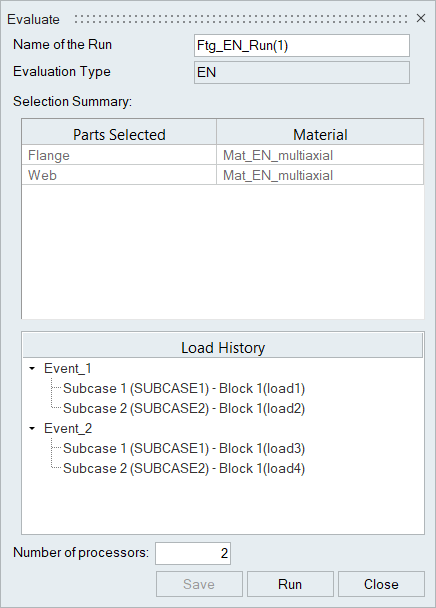

- Select the EN module and define its required parameters

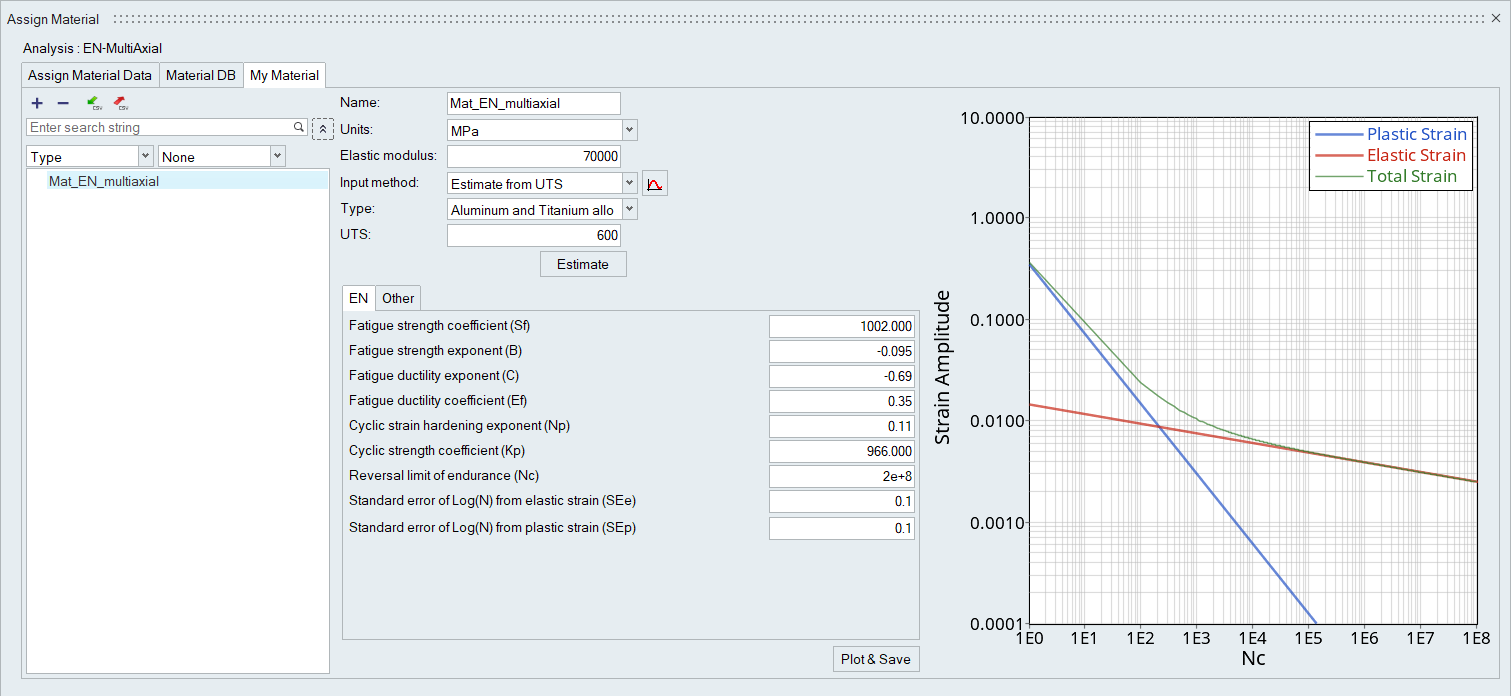

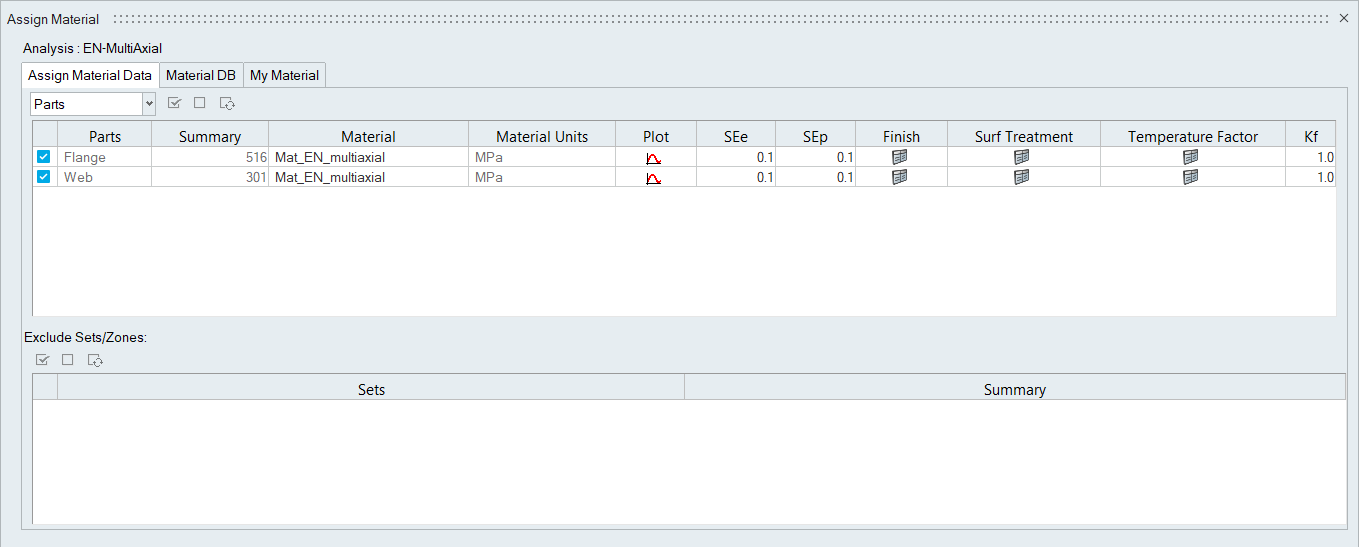

- Create and assign materials

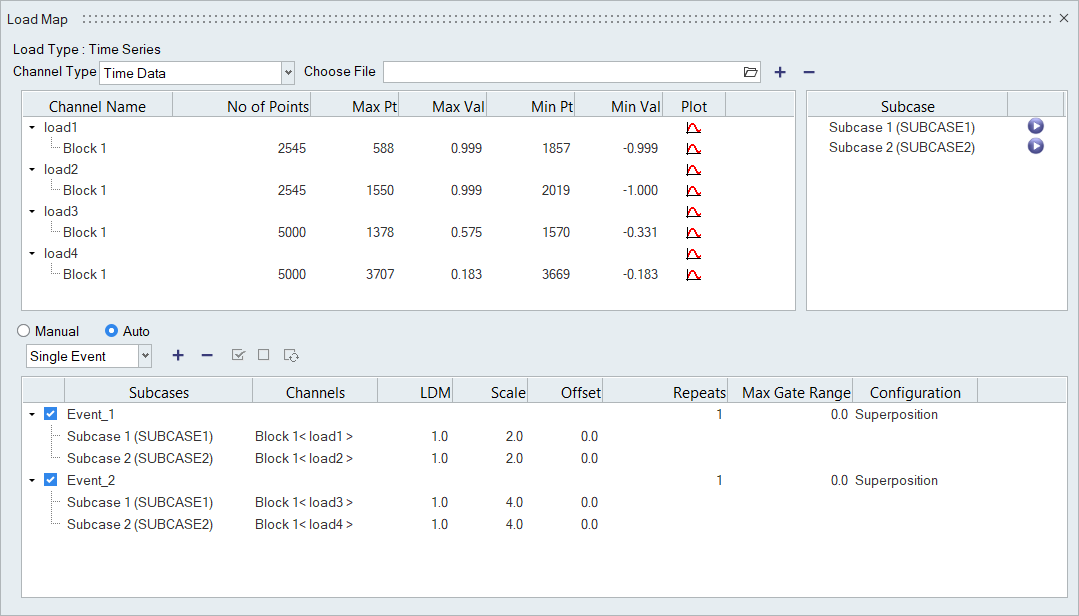

- Assign load histories for scaling the stresses from FEA subcases

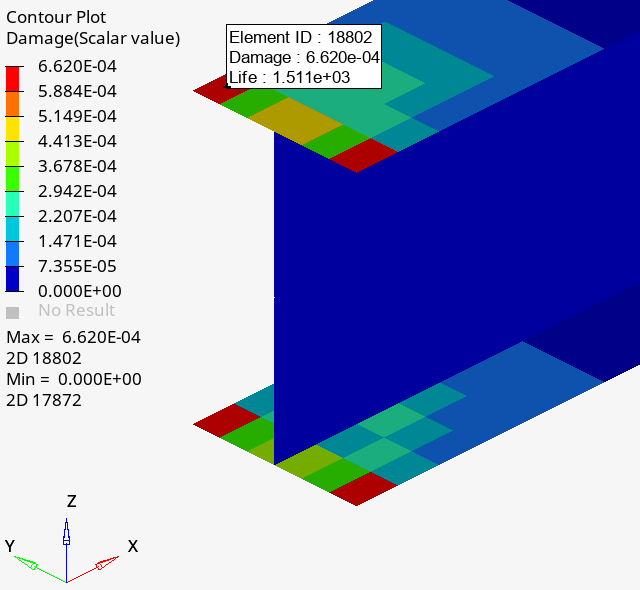

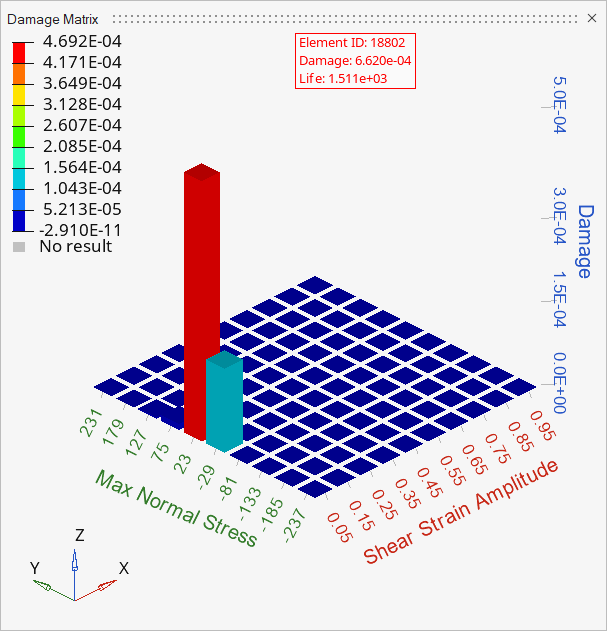

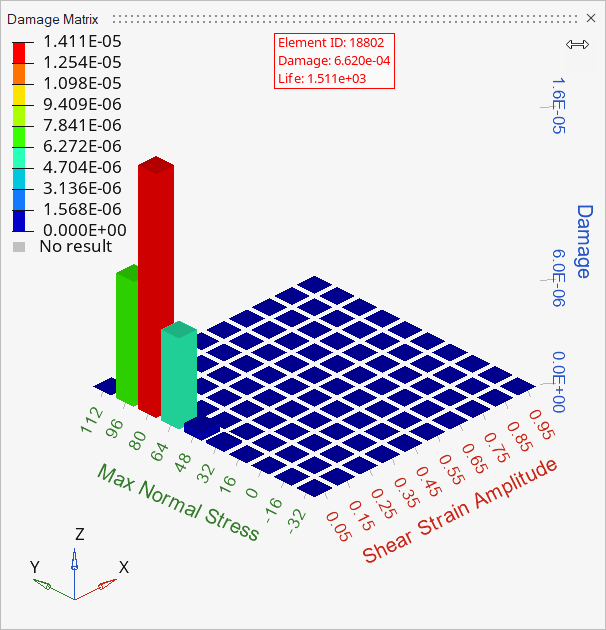

- Evaluate and view results

- HL-1030\Ibeam.h3d

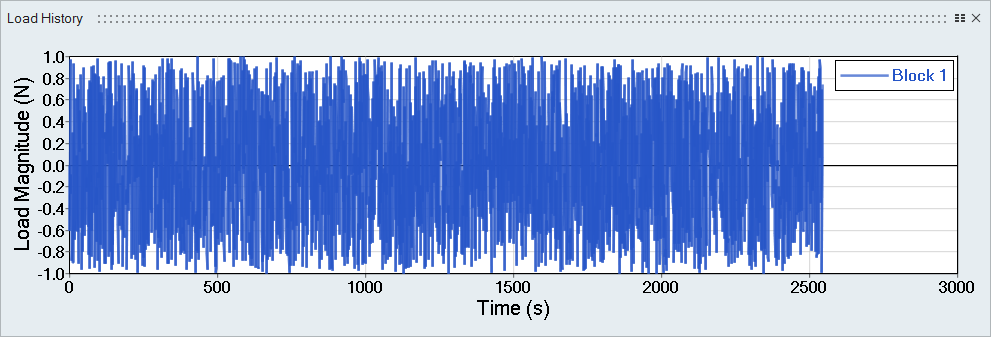

- Load_History_Files\load1.csv

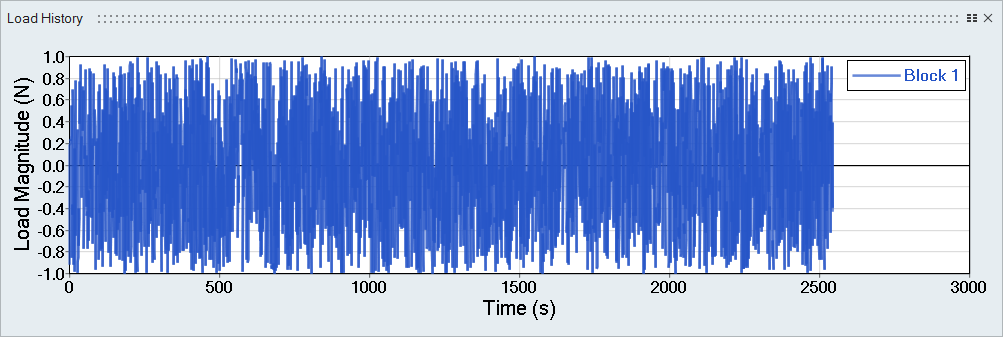

- Load_History_Files\load2.csv

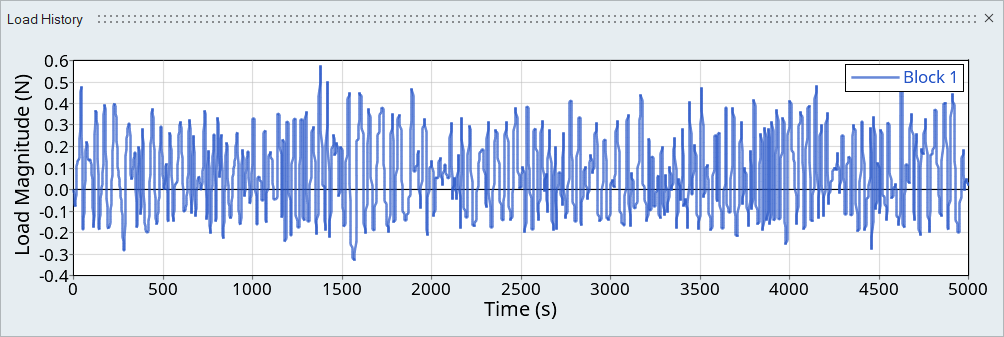

- Load_History_Files\load3.csv

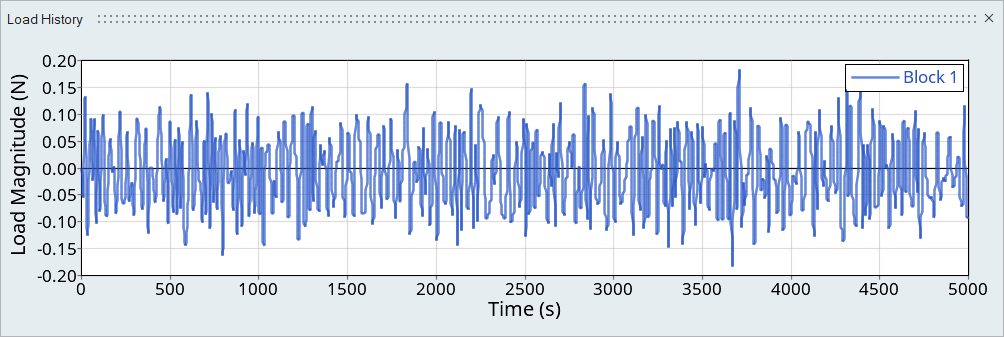

- Load_History_Files\load4.csv