Probes

As specified in the Probe Definitions chapter, it is possible to define probes in several ways. First important distinction is the shape of each probe.

- volumeprobe

- Spherical shape

- surfaceprobe

- Cylindrical shape

- solidprobe

- Spherical shape

- flowrateprobe

- Arbitrary number of angles prism (arbitrary 2D shape as a prism base).

The volume, surface and solid probes are defined by their geometric features and do not require any particle stencil generation (they are created within the solver).

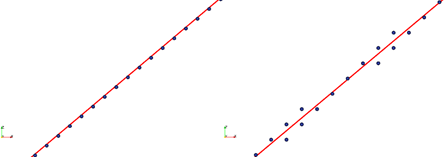

However, the flowrateprobe is specifically defined by a particle stencil which is written in a probe file that is contained within the case root folder. The flowrateprobe particle stencil can be of arbitrary 2D shape, implying that all particles in the stencil need to be co-planar (Figure 1).

It is important that all probes effectively have a 3D shape, as due to the Lagrangian nature of the code, particle flux needs to be considered and it is difficult to do so with a purely 2D entity. In the case of the volume and solid probes, the sphere radius can be defined. Varying the value of the sphere radius will simply cause a larger or smaller number of particles being considered when extracting the variable values. The user should be aware of this. The default value of the radius is set to 3*dx, which is equivalent to the particle smoothing length size.

For the surface probe – the shape is cylindrical, where the flow is measured along the direction of the cylinder axis. In this situation the 3rd dimension is the thickness (height) of the cylinder. Analogously to the radius of the volume and solid probe, the cylinder thickness of the surface probe will impact the number of particles being considered when passing through the middle of the cylinder and this can reflect on the final output. The default value of the cylinder thickness is equal to dx (1 particle pitch thickness). Keeping the default value is recommended. The fairly thin cylinder shape of dx minimizes the likely hood of error due to non-perpendicular flow or recirculation that might occur in the vicinity of any given surface probe. If you decide to change the thickness of the surface probe they need to be aware of potential negative effects that could arise due to flow irregularities around the probe.

To ensure proper functioning of the probes, it is strongly advised that the probes remain completely in the simulation domain. This is to say that the probes should not be positioned in such a way that any part of the probe is exiting the computational domain of the case.

It is also useful to note that when using volume, surface or flow rate probes for measuring fluid properties or mass flow – it is allowed that overlaps between these probes and WALL or MOVINGWALL phases exist. The probes in that case will consider only the FLUID portion of the particles that are withing the measurement geometry of the probe. Vice versa, when the solid probes are used, the FLUID particles will be ignored and the output will be provided only for WALL or MOVINGWALL phases.