HL-T: 1060 Seam Weld (Fillet)

In this tutorial you will:

- Import a model to HyperLife

- Select the Weld module and define its required parameters

- Create materials and assign them to the welds and sheet groups

- Assign load histories for scaling the stresses from FEA subcases

- Evaluate and view results

Before you begin, copy the file(s) used in this tutorial to your

working directory.

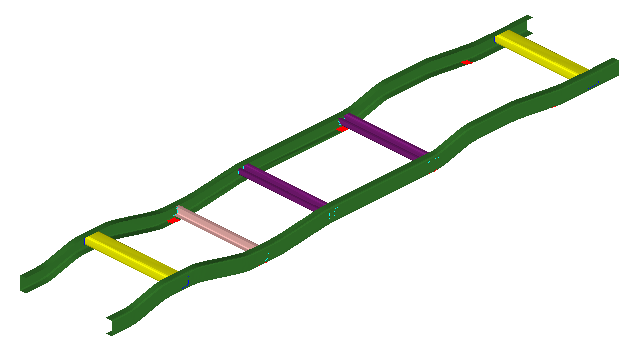

- HL-1060\Seam-Fillet.h3d

- HL-1060\Seam-Fillet.gpf

- Load_History_Files\load1.csv

- Load_History_Files\load2.csv

Import the Model

Note: Only OptiStruct and Nastran results are supported.

-

From the Home tools, Files tool group, click the Open Model tool.

Figure 1. -

From the Load model and result dialog, browse and select

HL-1060\Seam-Fillet.h3d for the model

file.

The Load Result field is automatically populated. For this tutorial, the same file is used for both the model and the result.Note: Seam weld analysis is performed using grid point forces, which can be made available with *.gpf files in the model directory. If no *.gpf file is present, the grid point forces should be included in the .h3d file.

-

Click Apply.

Figure 2.

Tip: Quickly import the model by dragging and

dropping the .h3d file from

a windows browser into the HyperLife

modeling window.

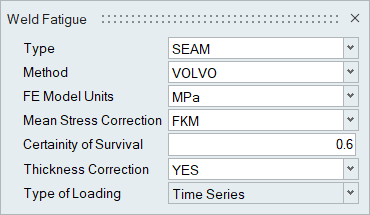

Define the Fatigue Module

-

From the Setup tools, click the arrow next to the

fatigue module icon and select the Weld tool from the

list of options.

Figure 3.The Weld dialog opens. - Set the type to SEAM.

- Set the certainty of survival to 0.6.

-

Accept all other default parameters.

Figure 4. - Exit the dialog.

Assign Materials

-

From the Setup tools, click the

Material tool.

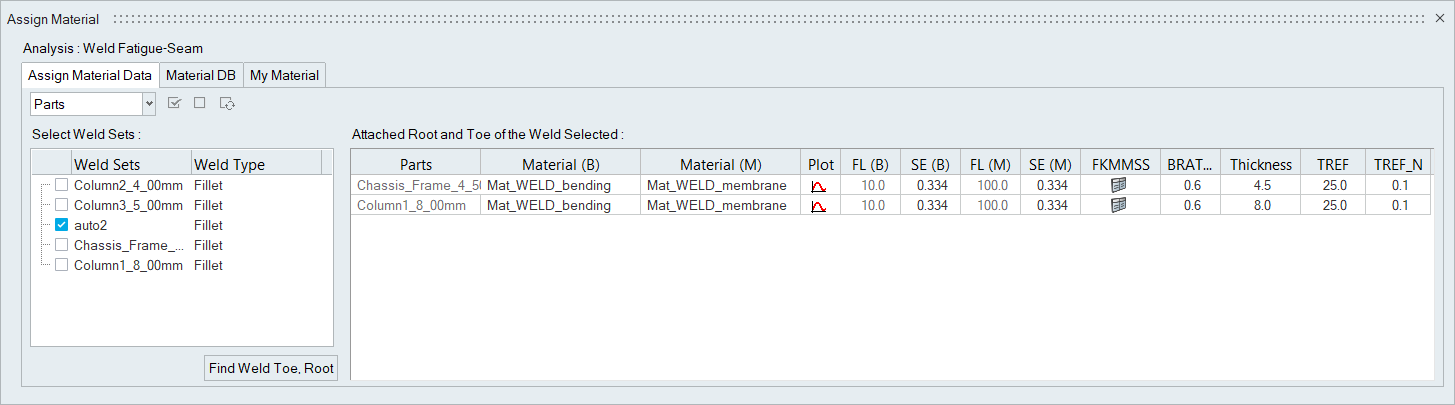

Figure 5.The Assign Material dialog opens. - Using the drop-down menu at the top, left of the dialog, change the components from Sets to Parts.

- In the Select Weld Parts window, activate the checkbox next to auto2.

-

Click Find Weld Toe, Root.

The adjacent attached components are displayed.

-

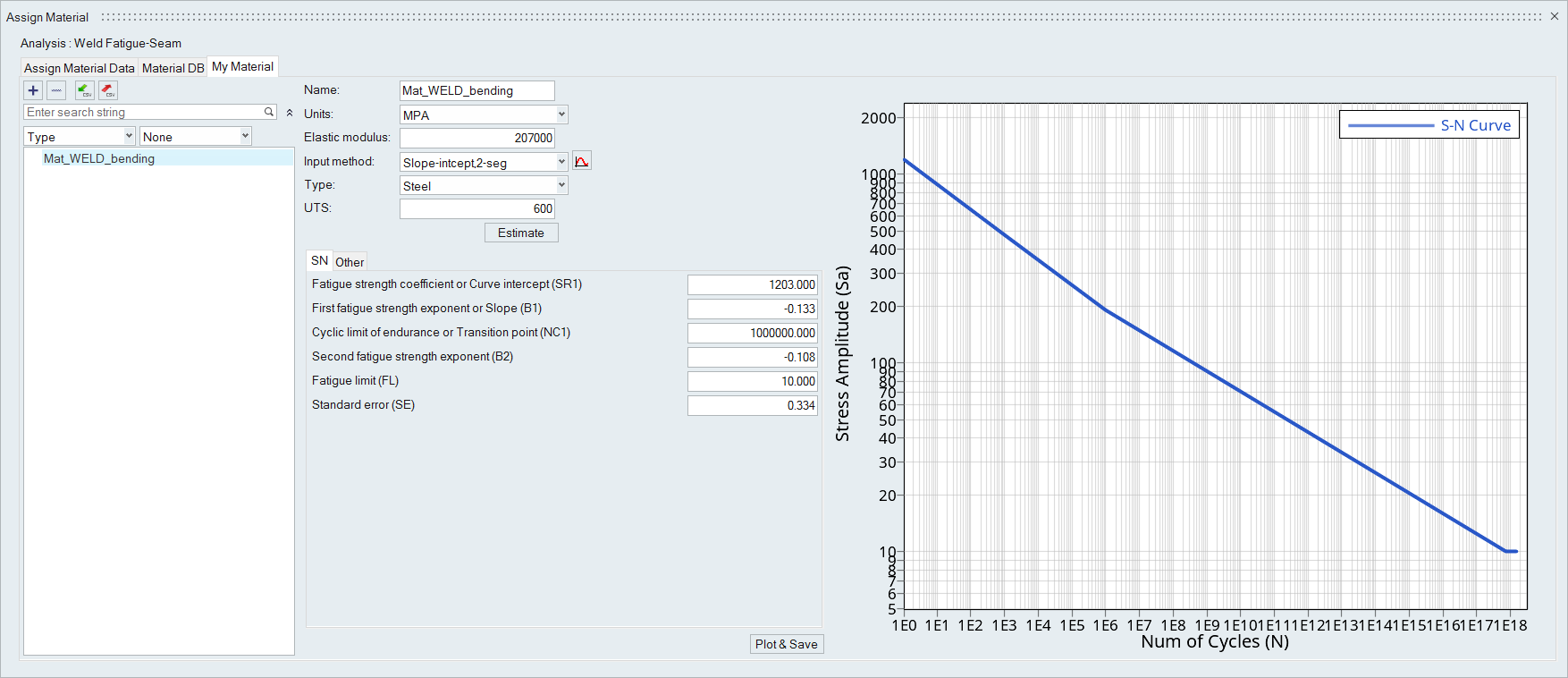

Create a bending material.

- Click the My Material tab.

-

Click

to create a new material.

to create a new material.

- Name the material Mat_WELD_bending.

- Change the Input method to Slope-intcept,2-seg.

- In the SN tab, set the Fatigue strength coefficient or Curve intercept (SR1) to 1203.

- Set the Fatigue limit to 10.

- Set the Standard error value to 0.334.

- Click the Other tab and ensure the Yield Strength is set to 250 and Poisson's Ratio is set to 0.333.

-

Accept all other default settings then click Plot &

Save.

Figure 6.

-

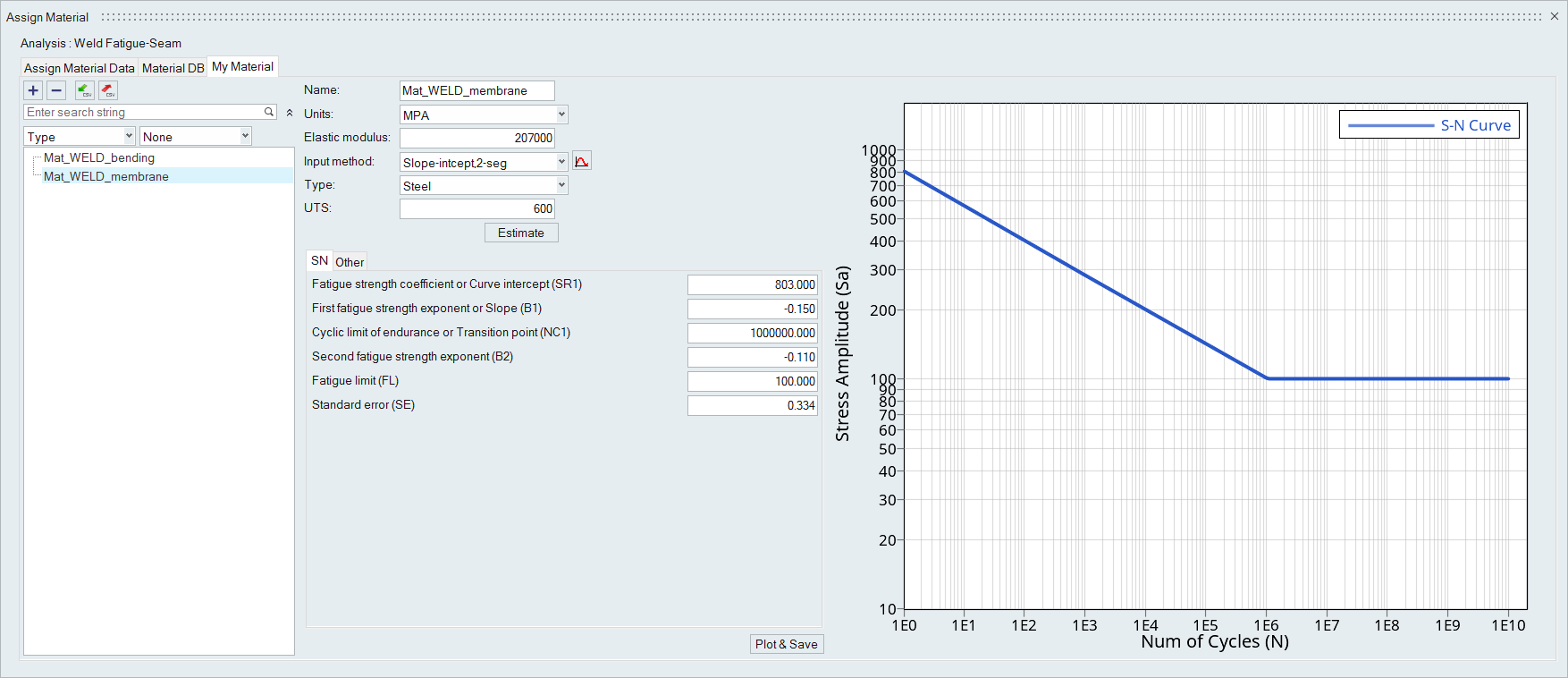

Create a membrane material.

-

Staying in the My Material tab, click

to create another material.

to create another material.

- Name the material Mat_WELD_membrane.

- Change the Input method to Slope-intcept,2-seg.

- In the SN tab, set the Fatigue strength coefficient or Curve intercept (SR1) to 803.000.

- Set the First fatigue strength exponent or Slope (B1) to -0.150.

- Set the Second fatigue strength exponent (B2) to -0.110.

- Set the Fatigue limit to 100.

- Set the Standard error value to 0.334.

- Click the Other tab and ensure the Yield Strength is set to 250 and Poisson's Ratio is set to 0.333.

-

Accept all other default settings then click Plot &

Save.

Figure 7.

-

Staying in the My Material tab, click

- Right-click on both Mat_WELD_bending and Mat_WELD_membrane and select Add to Assign Material List.

- Return to the Assign Material Data tab.

-

Set Mat_WELD_bending as Material (B) and

Mat_WELD_membrane as Material (M) for both

components.

The Material list is populated with the materials selected from Material Database and My Material.Note: The Material Database contains default bending and membrane materials for seam weld analyses.

- Set BRATIO to 0.6 for both components.

-

Set TREF_N to 0.1 for both components.

Figure 8. - Exit the dialog.

Assign Load Histories

-

From the Setup tools, click the

Load Map tool.

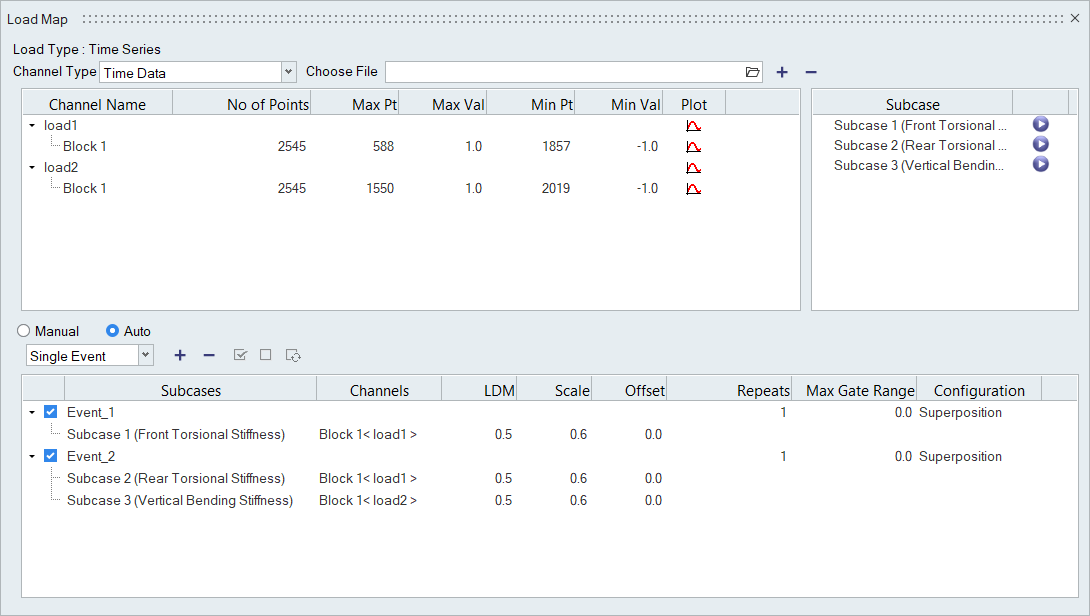

Figure 9.The Load Map dialog opens. - From the Channel Type drop-down menu at the top of the dialog, select Time Data.

-

Click

in the Choose File

field and browse for load1.csv.

in the Choose File

field and browse for load1.csv.

-

Click

to add the load case.

to add the load case.

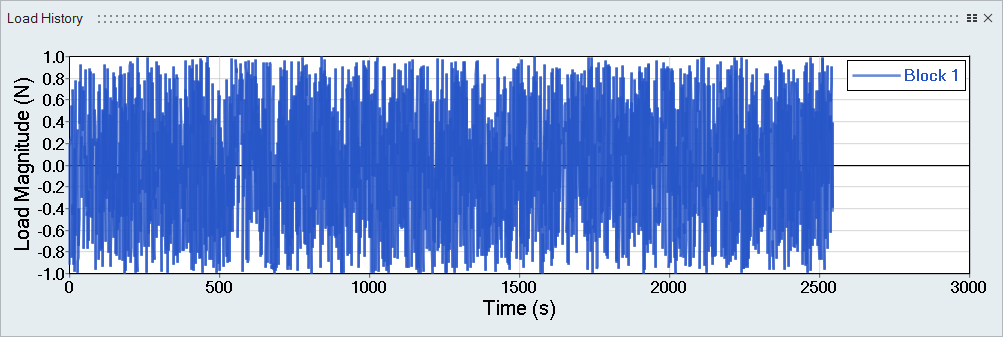

- Repeat steps 3 and 4 for load2.csv.

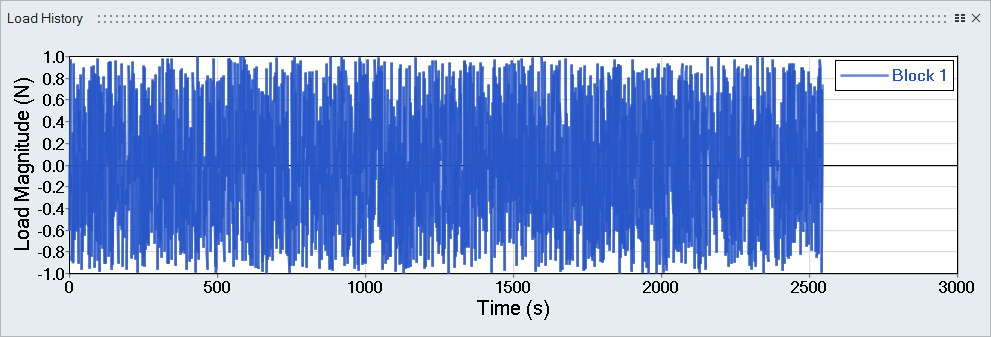

- Optional:

Click

to view a plot of the loads.

to view a plot of the loads.

Figure 10. Load 1

Figure 11. Load 2Tip: Expand the width of the dialog to view a clearer picture of the plot. - On the bottom half of the dialog, set the radio button to Auto for event creation.

-

Select both the Block 1 channel under load1 and

Subcase 1, then click

to create the first event.

to create the first event.

-

Next, select both Block 1 channels, Subcase

2, and Subcase 3 then click

.

A second event is created.Tip: Hold Control while left-clicking to select multiple options.

.

A second event is created.Tip: Hold Control while left-clicking to select multiple options. - Activate the checkboxes for the two events.

- Set the LDM to 0.5 for Subcase 1.

-

Right-click on the LDM field and select Apply value to all

events.

Subcases 2 and 3 inherit the LDM value.

-

Similarly, set the Scale to 0.6 for all three

subcases.

Figure 12. - Exit the dialog.

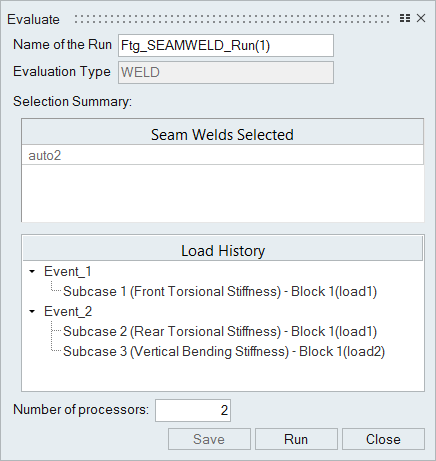

Evaluate and View Results

-

From the Evaluate tool group, click the Run Analysis tool.

Figure 13.The Evaluate dialog opens.

Figure 14. - Optional: Enter a name for the run.

-

Click Run.

Result files are saved to the home directory and the Run Status dialog opens.

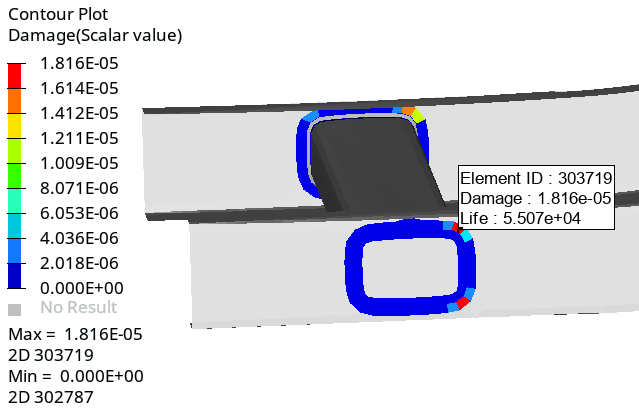

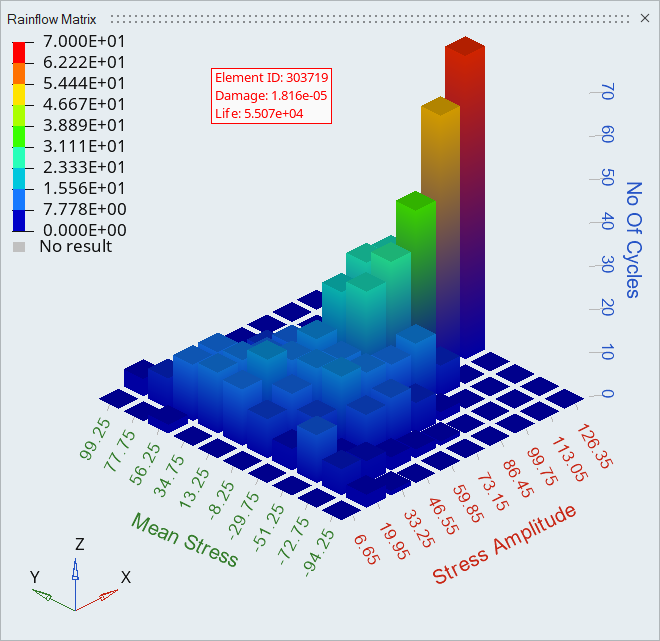

- Once the run is complete, click View Current Results.

-

Use the Results Explorer to

visualize various types of results.

Figure 15.

Figure 16.The life expectancy for the worst element is 5.607e4 cycles.