RD-T: 3050 Simplified Car Pole Impact

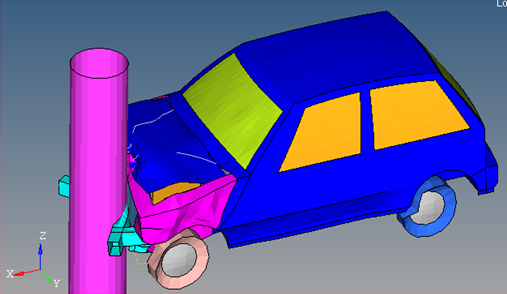

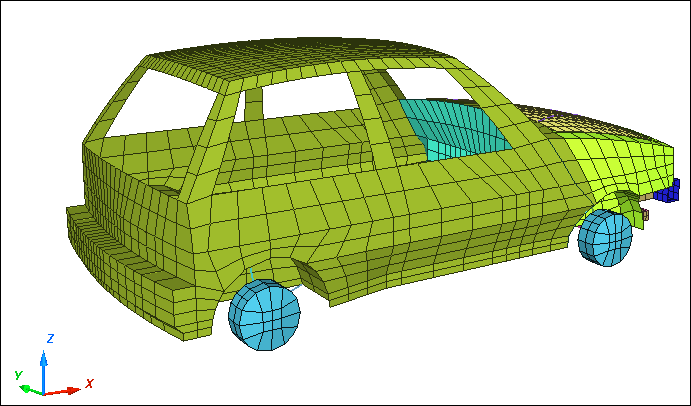

To simulate frontal pole test with a simplified full car.

Figure 1.

- UNITS: Length (mm), Time (s), Mass (ton), Force (N) and Stress (MPa)

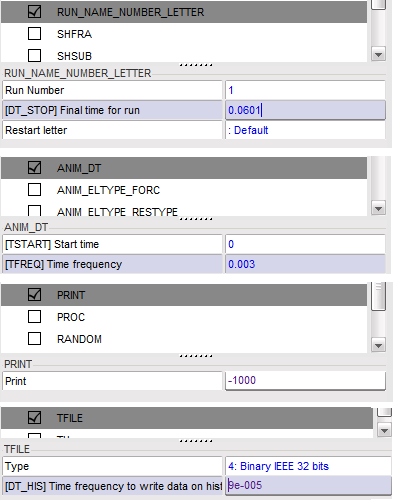

- Simulation time: Engine file (_0001.rad) [0 - 0.06 ms]

- An initial velocity of 15600 mm/s is applied on the car model to impact a rigid pole of radius 250 mm.

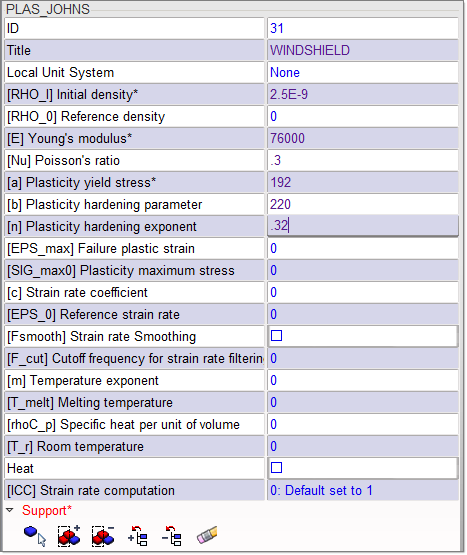

- Elasto-plastic Material /MAT/PLAS_JOHNS (WINDSHIELD)

[Rho_Initial] Initial Density = 2.5x10-9ton/mm3

[E] Young's Modulus = 76000 MPa

[nu] Poisson's Ratio = 0.3

[0] Yield Stress = 192 MPa

[K] Hardening Parameter = 220 MPa

[n] Hardening Exponent = 0.32

- Elasto-plastic Material /MAT/PLAS_JOHNS (STEEL)

[Rho_Initial] Initial Density = 7.9x10-9ton/mm3

[E] Young's Modulus = 210000 MPa

[nu] Poisson's Ratio = 0.3

[0] Yield Stress = 200 MPa

[K] Hardening Parameter = 450 MPa

[n] Hardening Exponent = 0.5

[SIG_max] Maximum Stress = 425 MPa

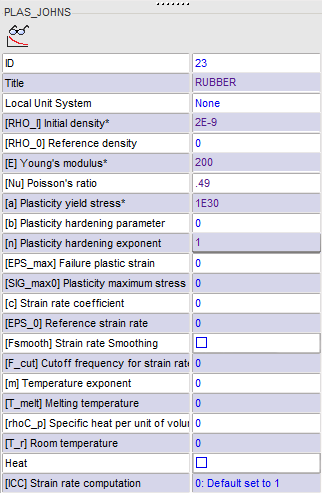

- Elasto-plastic Material /MAT/PLAS_JOHNS (RUBBER)

[Rho_Initial] Initial Density = 2x10-9ton/mm3

[E] Young's Modulus = 200 MPa

[nu] Poisson's Ratio = 0.49

[0] Yield Stress = 1e30MPa

[n] Hardening Exponent = 1

Start HyperCrash

- Open HyperCrash.

- Set the User profile to Radioss2020 and the Unit system to kN mm ms.kg.

- Set User Interface style as New.

- Set the working directory to <install_directory>/tutorials/hwsolvers/radioss.

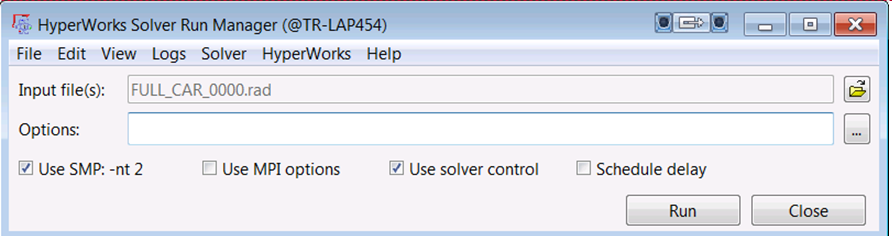

- Click Run.

- Click .

- In the input window, select full_car.nas.

- Click OK.

Create and Assign WINDSHIELD Material

Create and Assign RUBBER Material

Create and Assign STEEL Material

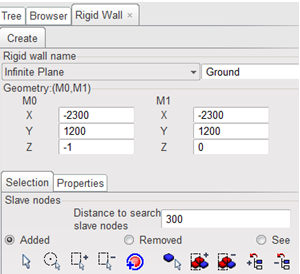

Create the Ground Rigid Wall

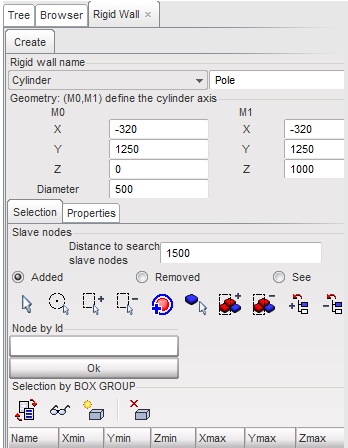

Creat3 Pole Rigid Wall

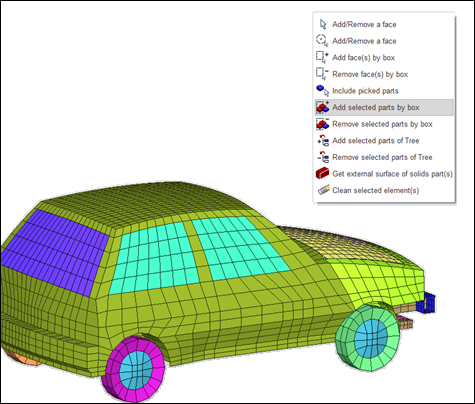

Create an Interface for the Full Car

Create an Interface between Engine and Radiator

Define Initial Velocities

- Click .

- In the Velocity list, right-click and select Create New.

- In the Title field, enter 35MPH.

- In the Tree window, highlight FULL_CAR.

- In the [Vx] field, enter 15600.

-

In the Initial Velocity tab, click in the [Gnod_id]

Support field. Move the cursor to the modeling window, right-click and select Add

selected parts of tree

.

.

- Click .

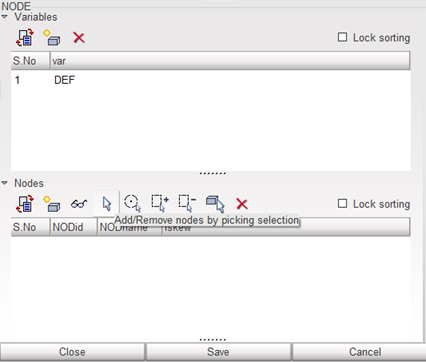

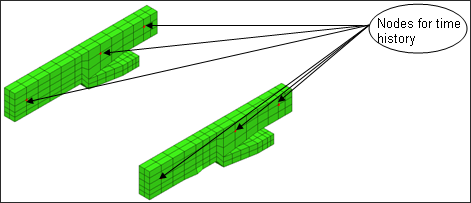

Define Time History Nodes

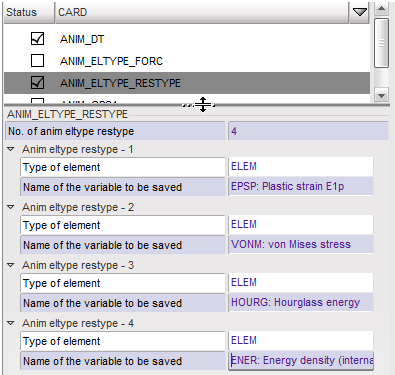

Export the Model

Expected Results

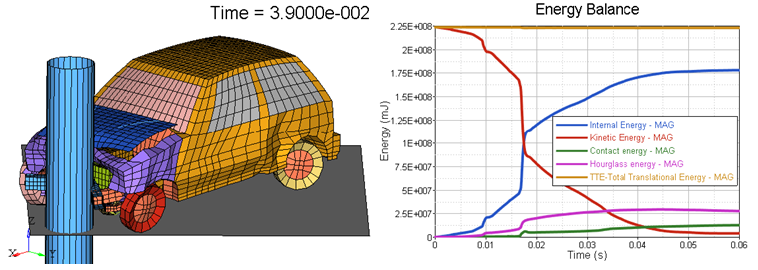

Figure 14. Final Deformation and Energy Balance Plot

to show

only these parts.

to show

only these parts.

to invert the tree selection.

to invert the tree selection.

.

.

to display the entire model.

to display the entire model.

and use

the mouse to drag a box to select the entire car in the

and use

the mouse to drag a box to select the entire car in the  in the second

table.

in the second

table.