Bergstrom-Boyce (/MAT/LAW95)

This law is a constitutive model for predicting the nonlinear time dependency of elastomer like materials. It uses a polynomial material model for the hyperelastic material response and the Bergstrom-Boyce material model to represent the nonlinear viscoelastic time dependent material response.

This law is only compatible with solid elements.

Material Parameters

- ¯I1=¯λ21+¯λ22+¯λ23

- ¯I2=¯λ−21+¯λ−22+¯λ−23

- ¯λi=J−13λi

- Cij and Di

- Material parameters

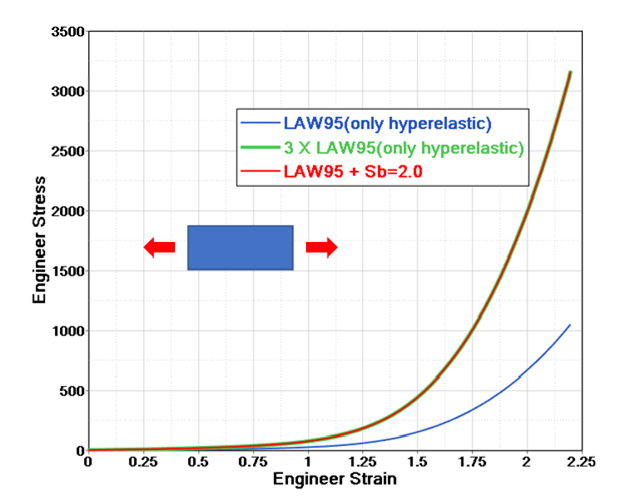

σ=¯σA+¯σB

Since WB=Sb⋅WA , then ¯σB=Sb⋅¯σA and total stress is σ=(1+Sb)⋅¯σA .

- Yeoh:

j=0

Where, C10,C20,C30 are not zero.Figure 4.

- Mooney-Rivlin:

i+j=1

Where, C10 and C01 are not zero and D2=D3=0 .

- Neo-Hookean:

Only C10 and D1 are not zero.

- Cij and Di

- Material parameters which can be calculated by completing a curve fit for quasi-static material test data.

RD-E: 5600 Hyperelastic Material with Curve Input, contains a curve fit example for Mooney-Rivlin and Yeoh material models. D1 can be calculated from the bulk modulus or left blank.

If the bulk modulus of the material is known, D1 can be calculated, or if D1 =0, an incompressible material is assumed.

Viscous (Rate) Effects

- ˜λ=√¯I13

- ¯σB

- Effective stress in Network B.

- A,ξ,M,C , and τref

- Input material parameters.

The material constants A , M and C are limited to a specific range of real values as defined in the Reference Guide. If limited data is available, a trial and error method 1 could be used to determine these constants. Start with the default values of ξ,M,C , Sb =1.6; and A =5. Next, compare model predictions with experimental data for at least one strain rate and adjust A to get a fit for the strain rate data.