Tire Contact Methods

- Single Point Contact

- Elliptical Cam Contact Model

Single Point Contact

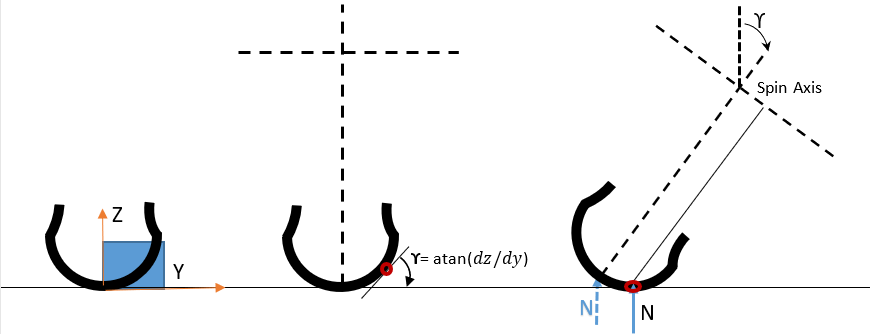

This is the default contact method that is used with the Fiala model. This model assumes the "disc" shape for the tire and rim and calculates the contact point at the intersection of the wheel plane with the road tangent.Motorbike tires have more curvature when compared with a car tire. At an inclination angle, the theoretical contact point shifts in the lateral direction. The geometry of the tire carcass is used to model this behavior.

Figure 1. From left: Tire cross section data needed for contact point evaluation | Tire at 0 camber angle | Tire at ϒ camber angle

| Parameters | Details | Unit |

|---|---|---|

| PA1 | Coefficient of the square root term in the contact length equation. | - |

| PA2 | Coefficient of the linear term in the contact length equation. | - |

| SECTION_PROFILE_TABLE | Table containing Z vs Y data of the tire cross section. | Length - Length |

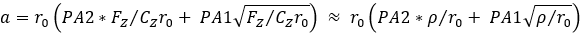

PA1 and PA2 shows the variation of contact patch length and width respectively. The size of the contact patch increases with increasing vertical load. The dimensions of the contact patch can be obtained by pressing the tire on carbon paper or by using ink.

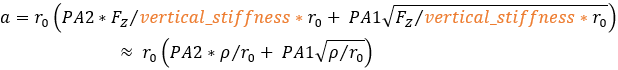

Contact Length Equation:

Contact Width Equation:

Where a, b are effective half-length and half-width of the contact patch.

is the width of the tire.

is the width of the tire.

The SECTION_PROFILE_TABLE contains the data of the tire carcass. The table should contain two columns as shown below:

The {x y} in the above table serves as the label. The table is read as per the TYDEX-W coordinate system and it represents the height variation of carcass with respect to points along the carcass width. Data for only a quarter of tire carcass is needed as the tire is assumed symmetric about XY plane in ISO system. The data points should be monotonically increasing otherwise data points will be ignored and the tire contact with will be calculated assuming a rectangular tire carcass.

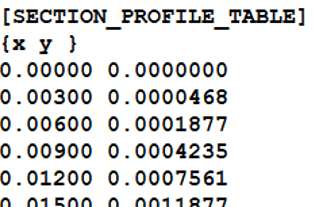

Elliptical Cam Contact Model

- Effective road height variation

- Effective slope variation

- Effective curvature

- Camber change

Figure 2. 3D Elliptical Cam Contact Arrangement

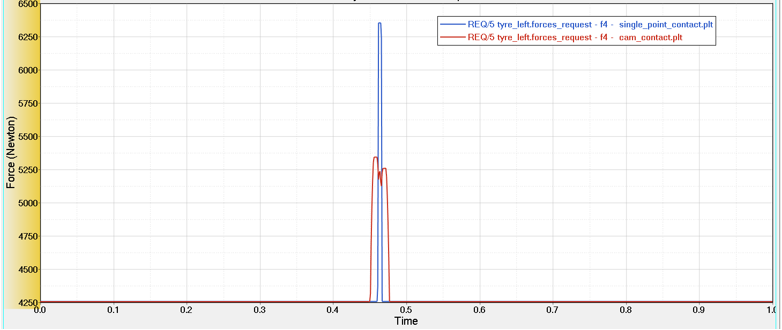

Figure 3. Vertical force at constant axle height when tire is rolled over a cleat (10 mm height, 50 mm length) at constant velocity of 10.833 m/sec (39km/h)

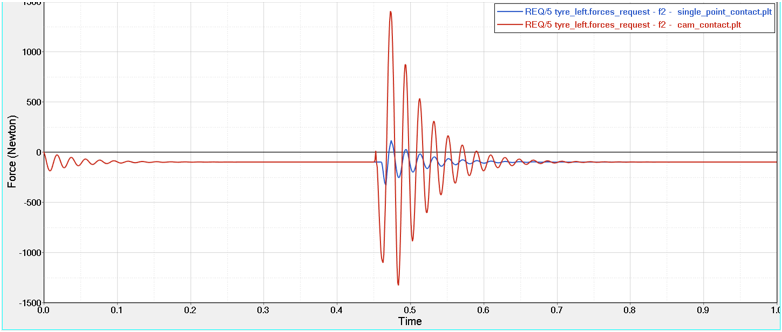

Figure 4. Longitudinal force at constant axle height when tire is rolled over a cleat (10 mm height, 50 mm length) at constant velocity of 10.833 m/sec (39km/h)

The results show that single point contact model predicts higher values of vertical force because it traces the obstacle, however the actual force experienced by the tire is less which is closely predicated using cam contact method.

Figure 5. Filtered Road Profile Using a Series of Cams

How to Use a Cam Contact Model

To use a cam contact method with Fiala Tire, the following attribute should exist in the [MODEL] block:

CONTACT_MODEL = '3D_ENVELOPING'

| Parameters | Details | Unit |

|---|---|---|

| PA1 | Coefficient of the square root term in the contact length equation. | - |

| PA2 | Coefficient of the linear term in the contact length equation. | - |

| PB1 | Coefficient of the cube root term in the contact width equation. (reserved) | - |

| PB2 | Coefficient of the linear term in the contact width equation. (reserved) | - |

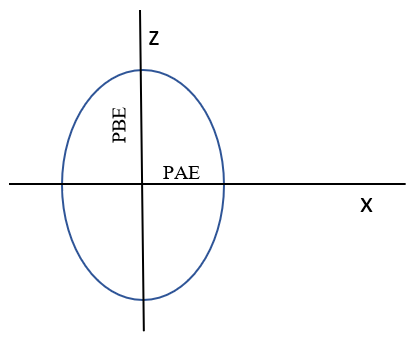

| PAE | Half of the ellipsoid length. | Length |

| PBE | Half of the ellipsoid height. | Length |

| PCE | Order of the ellipsoid. | - |

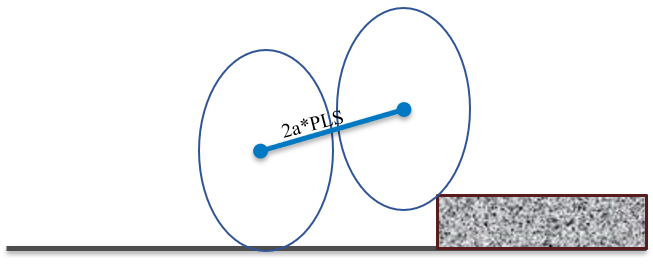

| PLS | Scaling of the distance between the front and rear ellipsoid. | - |

| ROAD_INCREMENT | Mesh size for the ellipsoid. | Length |

| N_WIDTH | Number of cams along the contact width. | - |

| N_LENGTH | Number of cams along the contact length. | - |

PA1 and PA2 show the variation of the contact patch length. The size of the contact patch increases with increasing vertical load. The dimension of the contact patch can be obtained by pressing tire on carbon paper or by using ink.

Contact Length Equation:

Where  is the tire penetration and

is the tire penetration and  is the unloaded radius of the tire.

is the unloaded radius of the tire.

PB1 and PB2 are not used to calculate the contact patch width.

Contact Width Equation:

Where a, b are effective half-length and half-width of the contact patch.

is the width of the tire.

is the width of the tire.

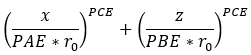

The equation for the shape of cam can be written as:

Figure 6. Cam Dimension

Figure 7. Cam with Two Point Follower

In case no data is available, a good estimate of PAE and PBE is equal to tire radius. The ellipse dimension can be calculated by measuring the outside contour of tire when it touches the obstacle. For PLS a 0.8 is a good value to use. ROAD_INCREMENT decides the meshing size of road it directly affects the computation time of model.