/FAIL/HASHIN

Block Format Keyword Describes the Hashin failure model. This failure model is available for Shell and Solid.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /FAIL/HASHIN/mat_ID/unit_ID | |||||||||

| Iform | Ifail_sh | Ifail_so | ratio | I_Dam | Imod | I_frwave | |||

| σt1σt1 | σt2σt2 | σt3σt3 | σc1σc1 | σc2σc2 | |||||

| σcσc | σf12σf12 | σm12σm12 | σm23σm23 | σm13σm13 | |||||

| ϕϕ | Sdel | τmaxτmax | ˙ε0˙ε0 | Tcut | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Soft | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fail_ID |

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier (Integer, maximum 10 digits) |

|

| Iform | Formulation flag.

(Integer) |

|

| Ifail_sh | Shell failure flag.

(Integer) |

|

| Ifail_so | Solid failure flag.

(Integer) |

|

| ratio | For

Isolid=2 or

Ifail_sh=2:

the element will be deleted, if more than ratio of

the layers (or integration points) have

failed. Default= 1.0 (Real) |

|

| I_Dam | Damage calculation flag. 6

(Integer) |

|

| Imod | Relaxation time calculation.

(Integer) |

|

| I_frwave | Failure propagation flag between neighbor elements.

(Integer) |

|

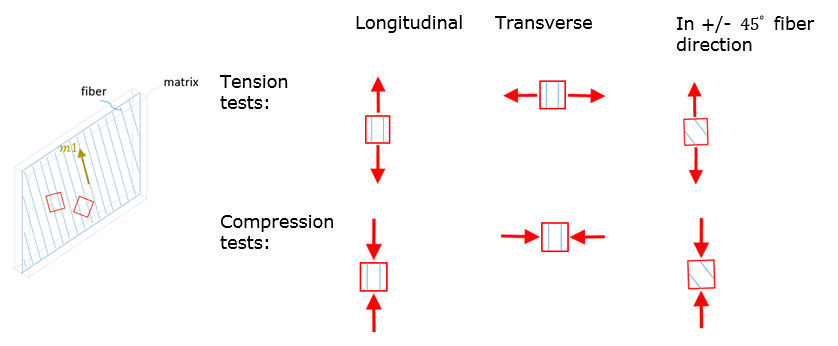

| σt1σt1 | Longitudinal tensile strength (in fiber

direction). Default = 1030 (Real) |

[Pa][Pa] |

| σt2σt2 | Transverse tensile strength (perpendicular to the

fiber direction). Default = 1030 (Real) |

[Pa][Pa] |

| σt3σt3 | Through thickness tensile strength. Default = 1030 (Real) |

[Pa][Pa] |

| σc1σc1 | Longitudinal compressive strength (in fiber

direction). Default = 1030 (Real) |

[Pa][Pa] |

| σc2σc2 | Transverse compressive strength (perpendicular to

the fiber direction). Default = 1030 (Real) |

[Pa][Pa] |

| σcσc | Crush strength. Default = 1030 (Real) |

[Pa][Pa] |

| σf12σf12 | Fiber shear strength. Default = 1030 (Real) |

[Pa][Pa] |

| σm12σm12 | Matrix shear strength 12. Default = 1030 (Real) |

[Pa][Pa] |

| σm23σm23 | Matrix shear strength 23. Default = 1030 (Real) |

[Pa][Pa] |

| σm13σm13 | Matrix shear strength 13. Default = 1030 (Real) |

[Pa][Pa] |

| ϕϕ | Coulomb friction Angle for matrix and

delamination < 90 degrees. Default = 0 (Real) |

[deg][deg] |

| Sdel | Delamination criteria scale factor. Default = 1.0 (Real) |

|

| τmaxτmax | Dynamic time relaxation. 5 Default = 1030 (Real) |

[s][s] |

| ˙ε0˙ε0 | Reference strain rate. Default = 10-30 (Real) |

|

| Tcut | Strain rate cutoff period. Default = τmaxτmax (Real) |

[s][s] |

| Soft | Reduction factor applied to failure criteria when

one of neighbor elements has already

failed. Only used if, I_frwave=2. 0.0. ≤ Soft ≤ 1.0 Default = 0.0 (Real) |

|

| fail_ID | (Optional) Failure criteria identifer. 4 (Integer, maximum 10 digits) |

Example (Composite)

#RADIOSS STARTER

/UNIT/1

unit for mat and failure

# MUNIT LUNIT TUNIT

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/COMPSH/1/1

composite material

# RHO_I

1.5E-6

# E11 E22 NU12 Iform E33

42 40 .05 1 .5

# G12 G23 G31 EPS_f1 EPS_f2

3.4 3 3 0 0

# EPS_t1 EPS_m1 EPS_t2 EPS_m2 dmax

0 0 0 0 .9999

# Wpmax Wpref Ioff IFLAWP ratio

0 0 5 0 0

# c EPS_rate_0 alpha ICC_global

0 2E-4 0 1

# sig_1yt b_1t n_1t sig_1maxt c_1t

.1 25 .1 0 0

# EPS_1t1 EPS_2t1 SIGMA_rst1 Wpmax_t1

0 0 0 0

# sig_2yt b_2t n_2t sig_2maxt c_2t

.1 20 .1 0 0

# EPS_1t2 EPS_2t2 sig_rst2 Wpmax_t2

0 0 0 0

# sig_1yc b_1c n_1c sig_1maxc c_1c

.005 800 .5 0 0

# EPS_1c1 EPS_2c1 sig_rsc1 Wpmax_c1

.08 .15 .1 0

# sig_2yc b_2c n_2c sig_2maxc c_2c

.005 2000 .5 0 0

# EPS_1c2 EPS_2c2 sig_rsc2 Wpmax_c2

0 0 0 0

# sig_12yt b_12t n_12t sig_12maxt c_12t

.004 83 .31 0 0

# EPS_1t12 EPS_2t12 sig_rst12 Wpmax_t12

.075 .085 .05 0

# GAMMA_ini GAMMA_max d3max

1E31 1E31 .9999

# Fsmooth Fcut

0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FAIL/HASHIN/1/1

# Iform Ifail_sh Ifail_so Ratio I_Dam Imod Ifrwave

2 1 0 0 1

# Sigma1_T Sigma2_T Sigma3_T Sigma1_C Sigma2_C

2 .525 1E30 1.7 1.7

# Sigma_C SigmaF_12 SigmaM_12 SigmaM_23 SigmaM_13

1E30 1E30 .075 1E30 1E30

# Phi Sdelam Tau_max EPS_DOT_0 Tcut

0 1 .01

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- Example of ratio: if ratio=0.5, and Ifail_sh=2 (or Ifail_so=2), the element will be deleted, if more than half of the layers (or integration points) failed.

- The 3D material failure model:

- Uni-directional lamina model:Tensile/shear fiber mode:

(1) F1=(〈σ11〉σt1)2+(σ212+σ213σf122)F1=(⟨σ11⟩σt1)2+(σ212+σ213σf122)Compression fiber mode:(2) F2=(〈σa〉σc1)2 F2=(⟨σa⟩σc1)2with, σa=−σ11+〈−σ22+σ332〉σa=−σ11+⟨−σ22+σ332⟩

Crush mode:(3) F3=(〈p〉σc)2F3=(⟨p⟩σc)2with, p=−σ11+σ22+σ333p=−σ11+σ22+σ333

Failure matrix mode:(4) F4=(〈σ22〉σt2)2+(σ23S23)2+(σ12S12)2F4=(⟨σ22⟩σt2)2+(σ23S23)2+(σ12S12)2Delamination mode:(5) F5=S2del[(〈σ33〉σt2)2+(σ23˜S23)2+(σ13S13)2]F5=S2del⎡⎣(⟨σ33⟩σt2)2+(σ23˜S23)2+(σ13S13)2⎤⎦Where,

S12=σm12+〈−σ22〉tanϕS23=σm23+〈−σ22〉tanϕS13=σm13+〈−σ33〉tanϕ˜S23=σm23+〈−σ33〉tanϕ

Note:(6) 〈a〉={a if a>00 if a<0 - Fabric lamina model:Tensile/shear fiber mode:

(7) F1=(〈σ11〉σt1)2+(σ212+σ213σfa2)(8) F2=(〈σ22〉σt2)2+(σ212+σ223σfb2)With σfa=σf12 , σfb=σf12σt2σt1

Compression fiber mode:(9) F3=(〈σa〉σc1)2with, σa=−σ11+〈−σ33〉(10) F4=(〈σb〉σc2)2with, σb=−σ22+〈−σ33〉

Crush mode:(11) F5=(〈p〉σc)2with, p=−σ11+σ22+σ333

Shear failure matrix mode:(12) F6=(σ12σm12)2Matrix failure mode:(13) F7=S2del[(〈σ33〉σt3)2+(σ23S23)2+(σ13S13)2]Where,

S13=σm13+〈−σ33〉tanϕS23=σm23+〈−σ33〉tanϕ

If the damage parameter is Fi ≥ 1.0, the stresses are decreased by using an exponential function to avoid numerical instabilities. A relaxation technique is used by decreasing the stress gradually:(14) σ(t)=f(t)⋅σd(tr)With,(15) f(t)=exp(−t−trτmax)and t≥tr

Where,- t

- Time

- tr

- Start time of relaxation when the damage criteria is assumed

- τmax

- Time of dynamic relaxation

- σd(tr)

- Stress at the beginning of damage

- Uni-directional lamina model:

- The damage value, D is 0 ≤ D ≤ 1. The

status for fracture is:

- Free, if 0 ≤ D > 1

- Failure, if D=1

with D=Max(F1,F2,F3,F4,F5) for uni-directional lamina model and D=Max(F1,F2,F3,F4,F5,F6,F7) for fabric lamina model. This damage value shows with /ANIM/BRICK/DAMA or /ANIM/SHELL/DAMA.

- The fail_ID is used with /STATE/BRICK/FAIL and /INIBRI/FAIL. There is no default value. If the line is blank, no value will be output for failure model variables in the /INIBRI/FAIL (written in .sta file with /STATE/BRICK/FAIL option).

- After the failure criterion is reached, the τmax value determines a period of time when the stress in the failed element is gradually reduced to zero. When the stress reaches 1% of stress value at the start of failure, the element is deleted. This is necessary to avoid instabilities coming from a sudden element deletion and a failure “chain reaction” in the neighboring elements. Even if the failure criterion is reached, the default value of τmax=1.0E30 results in no element deletion. Therefore, it is recommended to define τmax 10 times larger than the simulation time step.

- The I_Dam option improves damage calculation and stability calculating damage, it is not available for shell elements and material laws N° < 29 . It is available for the /MAT/LAW25 (CRASURV) law, if using /PROP/TYPE51 or /PLY and /STACK options.