spot comparison

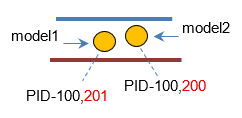

Spot comparison check configurations.

GUI Default Settings

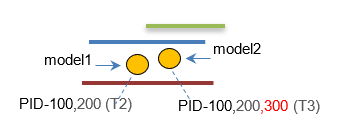

- tolerance

- Distance between two spot welds less/equal to this tolerance are

considered matching. Distance more than this tolerance is reported as

positional difference.Figure 1.

- slide-number

- The start number displayed on the top right corner of the PowerPoint slide.

- input-1

- Spot weld file 1.

- input-2

- Spot weld file 2 (same file cannot be selected).

- report

- Initial directory for report out path.

- action

- User action type to be executed.

- Check

- Only intersection check will be executed, no reports.

- Report

- Only Reports will be generated from the previous check.

- Both

- Check and Report generation will be executed in a sequence.

- extract-spot-cad-option

- CAD lines, points or solids are converted to spot weld file. A copy of

the spot weld file is stored in the input folder.Figure 2.

- extract-spot-method

- Logic to convert CAD to spot file.

- compname

- CAD names are used to recognize CAD spot data. These names are recognized via configuration file, name, connection and spot inputs.

- bbox

- Based on the location and surrounding parts, CAD is converted to spot weld file.

- position

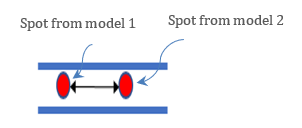

- Position (Coordinates) difference between spot weld 1 and spot weld 2

will be reported if ON. Allowable positional difference is less than

tolerance value.Figure 3.

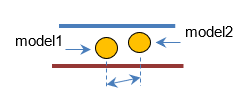

- part-id

- Part ID differences between spot weld 1 and spot weld 2 will be reported

if ON.Figure 4.

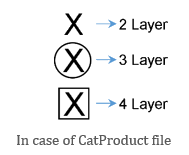

- layer

- #Layer, #Stack or #Link Components differences between spot weld 1 and

spot weld 2 will be reported if ON.Figure 5.