Modeling Guidelines

Workflow tips for modeling in SimSolid.

-

Check for free surfaces and merged parts.

- Import only solids.

-

Do not merge parts.

Part definition becomes complex, the solver works harder, and solution accuracy and performance can deteriorate if parts are merged.

-

Check for solids with curvature.

- If the faceting of those solids is coarse, bring in finer resolution of those parts.

- Do not import the entire assembly with finer resolution, it will slow down the solution considerably.

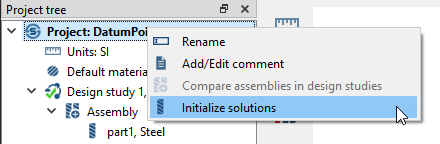

Figure 1. Settings > Geometry Import Settings

-

Check for geometry errors.

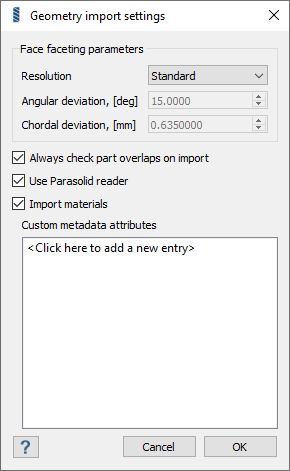

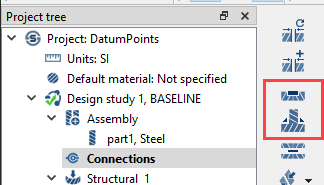

Figure 2. Assembly > check geometry error

-

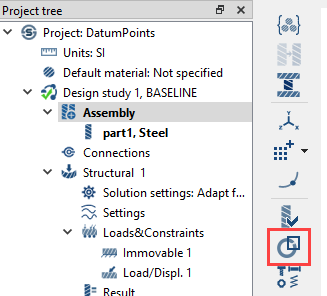

Make sure parts are classified correctly (bolts, nuts, springs, and so

on).

Figure 3. Assembly context menu > Show

-

Create weld connections, if applicable.

Connections in SimSolid should represent connections of the parts in the field.Figure 4. Connections > Seam/Spot Welds

-

Create auto-connections using normal resolution.

- Use small tolerance.

-

Identify and connect any free parts

.

.

- Make sure the structure is not over-constrained.

- Delete any redundant connections.

-

Identify connections with small number of points

.

.

- Edit those connections to have higher resolution.

-

Review parts with small relative volume.

- Verify that they have enough connection points.

Figure 5. Assembly > Review parts

-

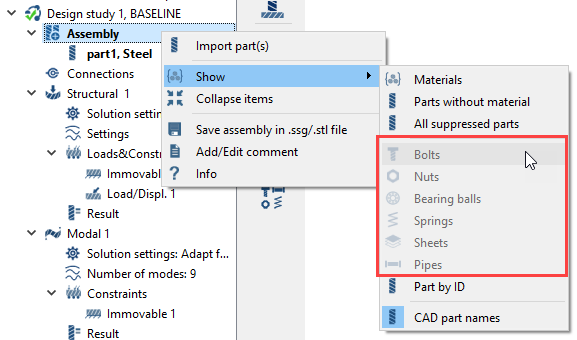

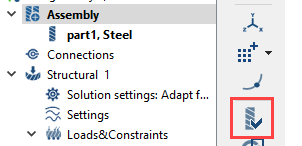

If project files from older versions are used, it is recommended to reset the

project.

- Right-click on the project and choose Initialize solution.

Figure 6. Project context menu > Initialize solutions