RD-E: 5000 INIVOL and Fluid Structure Interaction (Drop Container)

The aim of this example is to introduce /INIVOL for initial volume fractions of different materials in multi-material ALE elements, /SURF/PLANE for infinite plane, and fluid structure interaction (FSI) with a Lagrange container.

Options and Keywords Used

- Solid element (/BRICK)

- Material law (/MAT/LAW51 (MULTIMAT) and /ALE/MAT)

- ALE grid velocity (/ALE/GRID/DONEA)

- MUSCL scheme for ALE LAW51 (/ALE/MUSCL)

- Property (/PROP/TYPE14 (SOLID))

- Load (/INIVEL)

- Define initial volume (/INIVOL)

- Infinite surface plane (/SURF/PLANE)

- Fluid structure contact (/INTER/TYPE18)

Input Files

- <install_directory>/hwsolvers/demos/radioss/example/50_invol_and_fluid_structure_interaction/fsi_drop_container*

Model Description

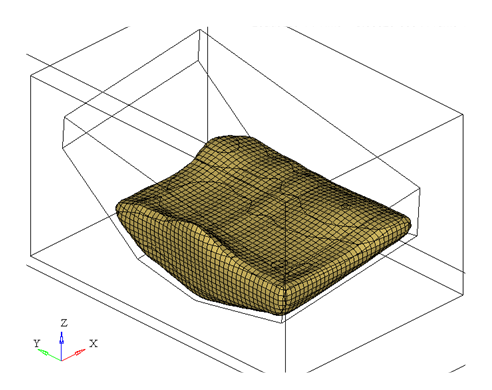

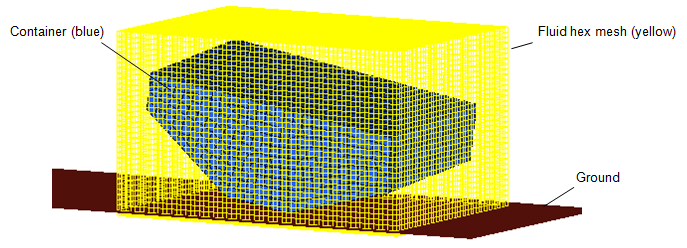

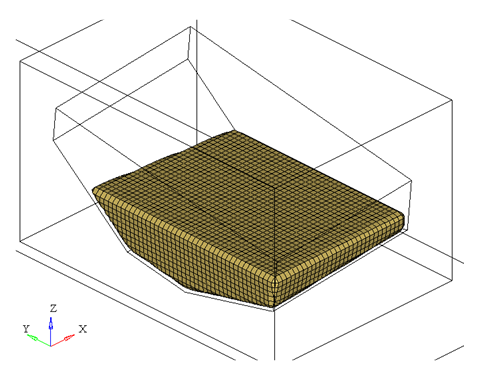

A hex mesh is created that fully encloses the structural container. The mesh size of the hex mesh should be ½ the size of the structural mesh. Ideally the hex mesh should also be ¼ of the structural mesh size in the direction of impact. To simplify this example, the hex mesh in this model does not adhere to the ¼ mesh size guideline.

Boundary Conditions

Units: mm, s, Mg, N, MPa

In one /MAT/LAW51 card, three different phases can be defined. The two phases are: Air and Water

- Reference density used in E.O.S (equation of state)

- 1.2e-12

- Initial density of air

- 1.2e-12

- Initial energy per unit volume

- 0.25

- Hydrodynamic cavitation pressure

- -1e-20

- Hydrodynamic coefficient C41

- 0.4

- Hydrodynamic coefficient C51

- 0.4

- Initial density of water

- 1e-9

- Hydrodynamic cavitation pressure

- -1e-20

- Hydrodynamic coefficient C03

- 0.10

- Hydrodynamic coefficient C13

- 2250 (Liquid bulk modulus)

Coupled Euler_Lagrange (CEL) Interface

- Master is the Lagrange structure

- Slave is the ALE fluid nodes

- ρ

- The (highest) fluid density

- υ

- The velocity.

- For incompressible models (ditching, sloshing, etc.), use the velocity of the event.

- For compressible but not supersonic, use the speed of the sound in the material.

- Compressible and transonic (Mach 0.8 to 1.0), replace the term ν2 with v⋅c

Where,

- υ

- Speed of the sound in the material

- c

- speed of sound in air

- Compressible and supersonic, use the velocity of the event

- For an explosion, use the Chapman Jouguet velocity

- v⋅c

- The surface area of the Lagrangian elements

- Gap

- The interface gap, as defined above

Simulation Iterations and Modeling

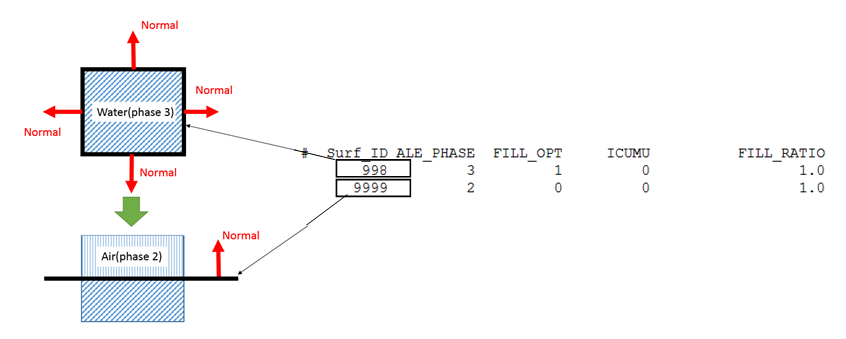

With /INIVOL, the water line can be defined in this part.

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /INIVOL/part_ID/inivol_ID | |||||||||

| inivol_title | |||||||||

| surf_ID | ALE_PHASE | FILL_OPT | ICUMU | FILL_RATIO | |||||

| surf_ID | ALE_PHASE | FILL_OPT | ICUMU | FILL_RATIO | |||||

| etc | etc | etc | etc | etc | |||||

| surf_IDn | ALE_PHASE | FILL_OPT | ICUMU | FILL_RATIO | |||||

/SURF/PART/998

Vessel_Surf_Part

85/INIVOL/86/10003507

INIVOL

# Surf_ID ALE_PHASE FILL_OPT ICUMU FILL_RATIO

998 3 1 0 1.0# Surf_ID ALE_PHASE FILL_OPT ICUMU FILL_RATIO

9999 2 0 0 1.0

- /ANIM/ELEM/DENSITY

- /ANIM/ELEM/VFRAC

You can contour the model and use section cut to see inside, or use iso-surface, as shown in Figure 4.

/ALE/MUSCL - Anti-diffusive Technique

/ALE/MUSCL allowing for a better localization of the interface between fluids, and much less numerical diffusion. In this example, use default for Beta.

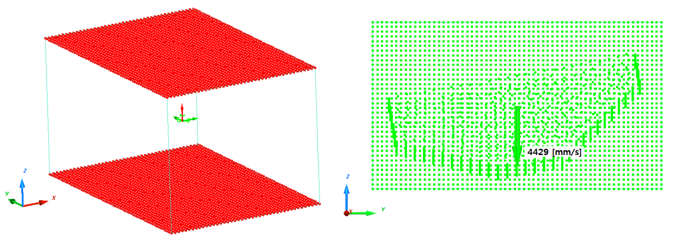

/ALE/GRID/DONEA - ALE Grid Velocity

This activates the J. Donea Grid Formulation, where the velocity of a given grid node depends on velocity and displacements of neighboring grid nodes.

Engine Control

It is recommended to use time step scale factor 0.5 for ALE in /DT/BRICK in order to keep computation stable, and use fac=1.0 in /UPWM/SUPG. This option provides better velocity field in Cartesian grids when ALE material velocity is not normal to brick faces.

Results

To see the movement of the water in the container, and iso-surface plot of results type "density” can be done. If the simple averaging method is used in HyperView, the results will look smoother.